<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

Home Search End mills long, semicoarse teeth, type N, Morse taper shank, code 421940, diameter 50 mm

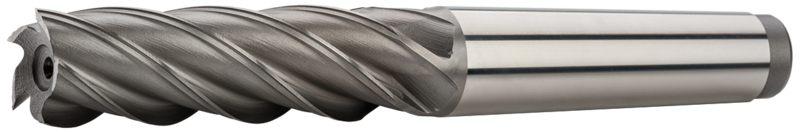

421940.500

High-speed steel HSS

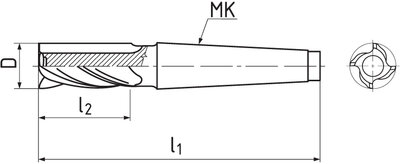

DIN 845

D

MK

l1

l2

Z

Item code

On stock

50

5

308

150

6

421940.500

Yes

421940.250, 421940.320 a 421940.500110 ≠ DIN 845

Cutting conditions

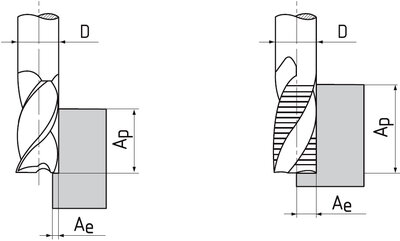

p e c fz (mm/z)Ø 20Ø 25Ø 32Ø 40Ø 50Ø 63

P.1 | Free-cutting steels, general construction steels

≤ 600 N/mm²

1xD

0,1xD

30

0.057

0.071

0.091

0.11

0.12

0.13

P.2 | General construction steels, steel castings

≤ 850 N/mm²

1xD

0,1xD

26

0.057

0.071

0.091

0.11

0.12

0.13

P.4 | Heat treatable steels

≤ 900 N/mm²

1xD

0,1xD

20

0.057

0.071

0.091

0.11

0.12

0.13

K.1 | Cast iron (≤ 240 HB)

≤ 820 N/mm²

1xD

0,1xD

25

0.057

0.071

0.091

0.11

0.12

0.13

Calculations of cutting conditions

Product attributes

Morse taper shank according to DIN 228 A.

Helix angle = 35°.

Rake angle = 12°.

High speed steel of average performance, it is applicable especially for cutters of smaller diameters and for milling of materials up to the strength of 900 MPa.

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

2025 © ZPS-FN a.s. | All right reserved