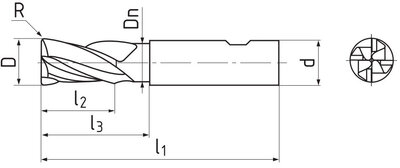

End mills long, 2 teeth cut to centre, 41°-42°, trochoidal milling, type N, weldon shank, code S143512T, diameter 8 mm

|

D

e 8 |

d

h 5 | l1 | l2 | l3 | Dn | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|---|

| 8 | 8 | 68 | 24 | 30 | 7,6 | 5 | S143512T.080 AlCr | No |

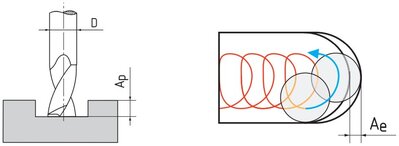

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 14 |

Ø 16 |

Ø 18 |

Ø 20 |

Ø 25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 3xD | 0,06xD | 190 | 0.072 | 0.096 | 0.12 | 0.144 | 0.168 | 0.192 | 0.216 | 0.24 | 0.3 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 3xD | 0,06xD | 170 | 0.072 | 0.096 | 0.12 | 0.144 | 0.168 | 0.192 | 0.216 | 0.24 | 0.3 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 3xD | 0,06xD | 80 | 0.072 | 0.096 | 0.12 | 0.144 | 0.168 | 0.192 | 0.216 | 0.24 | 0.3 |

| S.2 | Titanium, Titanium alloys | ≤ 1250 N/mm² | 3xD | 0,06xD | 130 | 0.072 | 0.096 | 0.12 | 0.144 | 0.168 | 0.192 | 0.216 | 0.24 | 0.3 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 6535 HB.

Helix angle = 41/42°.

Rake angle = 10°.

End face design

Oil coolant.

AlCr coating

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

End face design - radius

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.