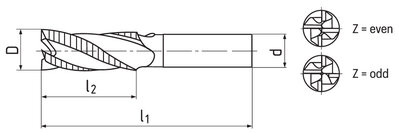

End mills long, 45°, typ HR, plain shank, code S119602, diameter 8 mm

|

D

h 10 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 8 | 8 | 63 | 19 | 4 | S119602.080 AlTiN | No |

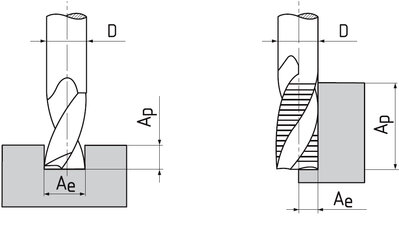

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 4 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1,5xD | 0,4xD | 180 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1,5xD | 0,4xD | 100 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1,5xD | 0,4xD | 80 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 1,5xD | 0,4xD | 90 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1,5xD | 0,4xD | 80 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1,5xD | 0,4xD | 140 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1,5xD | 0,4xD | 100 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 1,5xD | 0,4xD | 50 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

| S.2 | Titanium, titanium alloys | ≤ 1250 N/mm² | 1,5xD | 0,4xD | 70 | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 | 0.04 | 0.045 | 0.05 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Helix angle = 45°.

Rake angle = 6°.

End face design

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

For roughing operation and materials of medium and higher strength (up to 1200 MPa), surface roughness Ra 6,3 and more.

Feed direction possibility

Oil coolant.

Offers similar qualities as TiAlN, but even higher hardness. Substanial temperature stability. Designed for the most demanding applications. It provides excellent result mainly when combined with HSSE-PM steels (ASP 2030). The milling cutters manufactured from this steel are coated with AlTiN as standard.