Machine taps with straight flute, pasivation

|

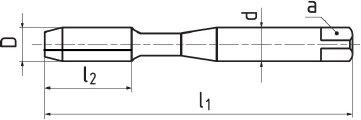

D

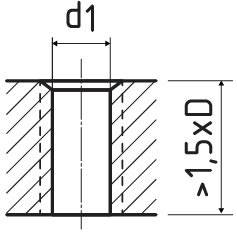

6 H | P | d | l1 | l2 | d1 | Z | a | Item code | On stock |

|---|---|---|---|---|---|---|---|---|---|

| M2 | 0,4 | 2,8 | 45 | 8 | 1,6 | 3 | 2,1 | MT11305.020 | Yes |

| M2,5 | 0,45 | 2,8 | 50 | 9 | 2,05 | 3 | 2,1 | MT11305.025 | Yes |

| M3 | 0,5 | 3,5 | 56 | 11 | 2,5 | 3 | 2,7 | MT11305.030 | Yes |

| M4 | 0,7 | 4,5 | 63 | 13 | 3,3 | 3 | 3,4 | MT11305.040 | Yes |

| M5 | 0,8 | 6 | 70 | 16 | 4,2 | 3 | 4,9 | MT11305.050 | Yes |

| M6 | 1 | 6 | 80 | 19 | 5 | 3 | 4,9 | MT11305.060 | Yes |

| M8 | 1,25 | 8 | 90 | 22 | 6,8 | 3 | 6,2 | MT11305.080 | Yes |

| M10 | 1,5 | 10 | 100 | 24 | 8,5 | 3 | 8 | MT11305.100 | Yes |

| M12 | 1,75 | 9 | 110 | 28 | 10,2 | 3 | 7 | MT11305.120 | Yes |

| M14 | 2 | 11 | 110 | 25 | 12 | 3 | 9 | MT11305.140 | Yes |

| M16 | 2 | 12 | 110 | 25 | 14 | 3 | 9 | MT11305.160 | Yes |

| M18 | 2,5 | 14 | 125 | 30 | 15,5 | 3 | 11 | MT11305.180 | Yes |

| M20 | 2,5 | 16 | 140 | 30 | 17,5 | 3 | 12 | MT11305.200 | Yes |

Cutting conditions

Material |

Strenght |

vc |

|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 10-15 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 10-15 |

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm² | 12-15 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 12-15 |

| N.3 | Aluminium cast alloys Si (Si > 12%) | ≤ 800 N/mm² | 12-15 |

Product attributes

For straight flutes with spiral point, for medium or long chipping material.

Lead of screw thread

ISO Metric coarse thread

Steamtempered (Black finish) is a process where a layer of iron oxide is formed on the surface of the tool. This layer increases the abrasion resistance of the blade, increases corrosion resistance and improves lubrication of the tool. The most effective use is for drill bits and taps.

Angle of thread

Thread standard

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.