<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

MT21575

High-speed steel HSS Co5

DIN 371, DIN 376

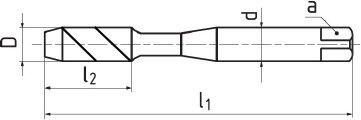

D

P

d

l1

l2

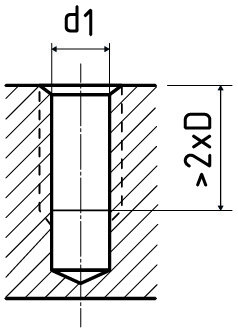

d1

Z

a

Item code

On stock

M3

0,5

3,5

56

5

2,5

3

2,7

MT21575.030

Yes

M4

0,7

4,5

63

7

3,3

3

3,4

MT21575.040

Yes

M5

0,8

6

70

8

4,2

3

4,9

MT21575.050

Yes

M6

1

6

80

10

5

3

4,9

MT21575.060

Yes

M8

1,25

8

90

13

6,8

3

6,2

MT21575.080

Yes

M10

1,5

10

100

15

8,5

3

8

MT21575.100

Yes

M12

1,75

9

110

18

10,2

3

7

MT21575.120

Yes

M14

2

11

110

20

12

3

9

MT21575.140

No

M16

2

12

110

20

14

4

9

MT21575.160

Yes

M18

2,5

14

125

25

15,5

4

11

MT21575.180

No

M20

2,5

16

140

25

17,5

4

12

MT21575.200

No

Cutting conditions

c

M.1 | Corrosion- and acid-proof steels

≤ 750 N/mm²

4-7

M.2 | Corrosion- and acid-proof steels

750 - 850 N/mm²

3-5

M.3 | Corrosion- and acid-proof steels

> 850 N/mm²

3-5

Product attributes

Designed for stainless steel

For straight or spiral flutes, for short chipping materials.

Lead of screw thread

ISO Metric coarse thread

Steamtempered (Black finish)

more +

Steamtempered (Black finish) is a process where a layer of iron oxide is formed on the surface of the tool. This layer increases the abrasion resistance of the blade, increases corrosion resistance and improves lubrication of the tool. The most effective use is for drill bits and taps.

Angle of thread

Thread standard

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.

2025 © ZPS-FN a.s. | All right reserved