<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

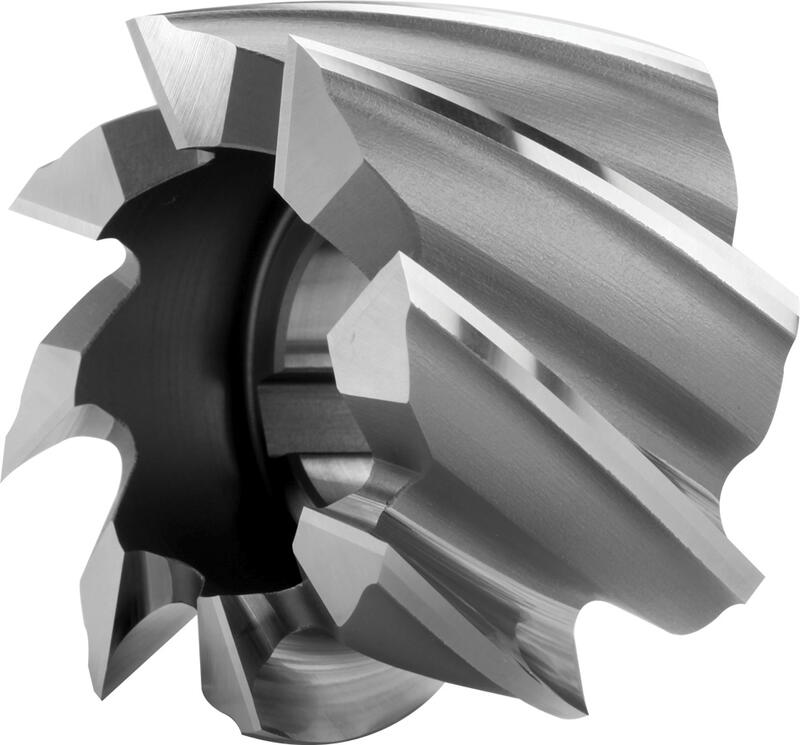

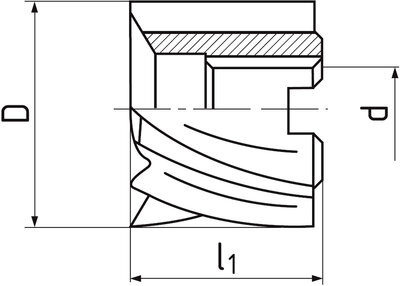

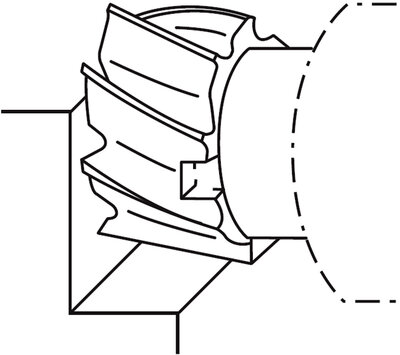

630275V

High-speed steel HSS Co5

DIN 1880

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z)

Ø 40 |

Ø 50 |

Ø 63 |

Ø 80 |

Ø 100 |

Ø 125 |

| P.3 | Tool steels low alloyed |

≤ 1100 N/mm² |

0,8xl1 |

0,75xD |

18 |

0.08 |

0.085 |

0.1 |

0.105 |

0.11 |

0.115 |

| P.4 | Heat treatable steels |

≤ 900 N/mm² |

0,8xl1 |

0,75xD |

25 |

0.08 |

0.085 |

0.1 |

0.105 |

0.11 |

0.115 |

| P.5 | Tool steels high alloyed |

≤ 1100 N/mm² |

0,8xl1 |

0,75xD |

18 |

0.08 |

0.085 |

0.1 |

0.105 |

0.11 |

0.115 |

| P.6 | Tool and treated steels |

> 1100 N/mm² |

0,8xl1 |

0,75xD |

16 |

0.056 |

0.06 |

0.07 |

0.074 |

0.077 |

0.081 |

| M.2 | Corrosion- and acid-proof steels |

750 - 850 N/mm² |

0,8xl1 |

0,75xD |

10 |

0.08 |

0.085 |

0.1 |

0.105 |

0.11 |

0.115 |

| K.2 | Cast iron (> 240 HB) |

> 800 N/mm² |

0,8xl1 |

0,75xD |

22 |

0.08 |

0.085 |

0.1 |

0.105 |

0.11 |

0.115 |

| S.1 | Chrome-nickel alloys |

≤ 1500 N/mm² |

0,8xl1 |

0,75xD |

8 |

0.056 |

0.06 |

0.07 |

0.074 |

0.077 |

0.081 |

Calculations of cutting conditions

2026 © ZPS-FN a.s. | All right reserved