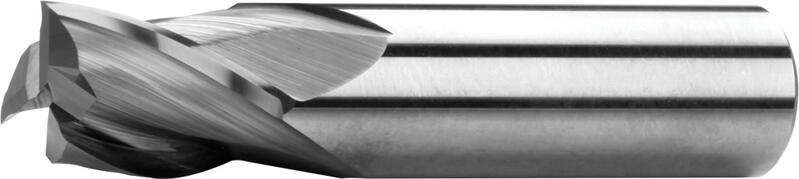

Mini end mills, 1 tooth cut over centre, 30°, plain shank

|

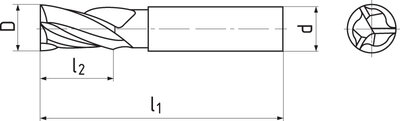

D

h 10 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 0,5 | 3 | 40 | 1,5 | 3 | C160402.005 | Yes |

| 0,6 | 3 | 40 | 1,5 | 3 | C160402.006 | No |

| 0,8 | 3 | 40 | 2 | 3 | C160402.008 | Yes |

| 1 | 3 | 40 | 2 | 3 | C160402.010 | Yes |

| 1,2 | 3 | 40 | 2 | 3 | C160402.012 | Yes |

| 1,5 | 3 | 40 | 2 | 3 | C160402.015 | Yes |

| 1,8 | 3 | 40 | 2 | 3 | C160402.018 | No |

| 2 | 6 | 40 | 4 | 3 | C160402.020 | Yes |

| 2,5 | 6 | 40 | 5 | 3 | C160402.025 | Yes |

| 3 | 6 | 40 | 5 | 3 | C160402.030 | Yes |

| 3,5 | 6 | 40 | 6 | 3 | C160402.035 | No |

| 4 | 6 | 40 | 7 | 3 | C160402.040 | No |

| 4,5 | 6 | 40 | 8 | 3 | C160402.045 | No |

| 5 | 6 | 40 | 8 | 3 | C160402.050 | Yes |

| 5,5 | 6 | 40 | 8 | 3 | C160402.055 | No |

| 5,8 | 6 | 40 | 8 | 3 | C160402.058 | No |

| 6 | 6 | 40 | 8 | 3 | C160402.060 | Yes |

| 6,8 | 8 | 45 | 10 | 3 | C160402.068 | No |

| 7 | 8 | 45 | 10 | 3 | C160402.070 | Yes |

| 7,8 | 8 | 45 | 10 | 3 | C160402.078 | No |

| 8 | 8 | 45 | 11 | 3 | C160402.080 | Yes |

| 8,7 | 10 | 50 | 11 | 3 | C160402.087 | No |

| 9 | 10 | 50 | 11 | 3 | C160402.090 | No |

| 9,7 | 10 | 50 | 11 | 3 | C160402.097 | No |

| 10 | 10 | 50 | 13 | 3 | C160402.100 | Yes |

| 12 | 12 | 55 | 15 | 3 | C160402.120 | No |

Cutting conditions

Material |

Strength |

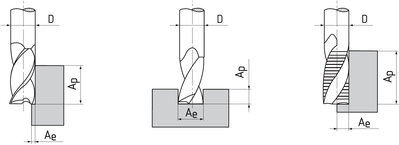

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 0,5xD | 0,1xD | 140 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 0,5xD | 0,1xD | 85 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 0,5xD | 0,1xD | 65 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 0,5xD | 0,1xD | 70 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 0,5xD | 0,1xD | 60 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 0,5xD | 0,1xD | 105 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 0,5xD | 0,1xD | 85 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 0,5xD | 0,1xD | 45 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

| S.2 | Titanium, Titanium alloys | ≤ 1250 N/mm² | 0,5xD | 0,1xD | 55 | 0.011 | 0.021 | 0.028 | 0.035 | 0.042 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility