End mills short, 1 tooth cut over centre, 25°, type N, plain shank

|

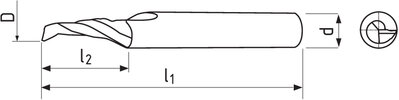

D

h10 | d | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 3 | 6 | 50 | 8 | 1 | S100502.030 | Yes |

| 4 | 6 | 54 | 11 | 1 | S100502.040 | Yes |

| 5 | 6 | 54 | 13 | 1 | S100502.050 | Yes |

| 6 | 6 | 54 | 13 | 1 | S100502.060 | No |

| 8 | 8 | 58 | 19 | 1 | S100502.080 | Yes |

| 10 | 10 | 66 | 22 | 1 | S100502.100 | Yes |

| 12 | 12 | 73 | 26 | 1 | S100502.120 | Yes |

Cutting conditions

Material |

Strength |

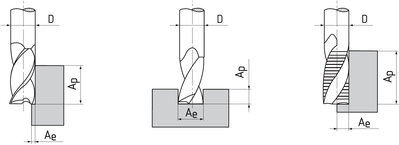

Ap |

Ae |

Vc |

fz(mm/z) Ø3 |

Ø4 |

Ø5 |

Ø6 |

Ø8 |

Ø10 |

Ø12 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm² | 0,3xD | 1xD | 250 | 0,023 | 0,03 | 0,038 | 0,045 | 0,06 | 0,075 | 0,09 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 0,3xD | 1xD | 250 | 0,023 | 0,03 | 0,038 | 0,045 | 0,06 | 0,075 | 0,09 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 0,3xD | 1xD | 250 | 0,023 | 0,03 | 0,038 | 0,045 | 0,06 | 0,075 | 0,09 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Lead of helix 25°.

End face design

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

For machining of soft materials, for example aluminium and non-ferrous metals.

Feed direction possibility

Oil coolant.

The polished surface improves chip evacuation in soft or sticky non-ferrous materials. Polishing facilitates chip evacuation and prevents material sticking to cutting edges and grooves.