End mills long, fine teeth, 45°, type HPC, weldon shank, coating AlCrN

|

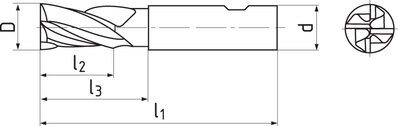

D

e 8 |

d

h 5 | l1 | l2 | l3 | Dn | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|---|

| 6 | 6 | 57 | 13 | 19 | 5,7 | 6 | S151712.060 AlCrN | No |

| 8 | 8 | 63 | 19 | 25 | 7,6 | 6 | S151712.080 AlCrN | No |

| 10 | 10 | 72 | 22 | 30 | 9,5 | 6 | S151712.100 AlCrN | Yes |

| 12 | 12 | 83 | 26 | 36 | 11,5 | 6 | S151712.120 AlCrN | No |

| 16 | 16 | 92 | 32 | 42 | 15,5 | 6 | S151712.160 AlCrN | No |

| 20 | 20 | 104 | 38 | 52 | 19,5 | 8 | S151712.200 AlCrN | Yes |

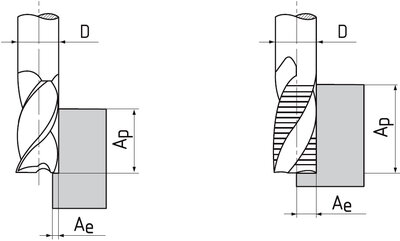

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1,5xD | 0,015xD | 175 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1,5xD | 0,015xD | 120 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1,5xD | 0,015xD | 150 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1,5xD | 0,015xD | 110 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 1,5xD | 0,015xD | 180 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

| H.2 | Hardened materials (54 - 60 HRC) | 1920 - 2210 N/mm² | 1,5xD | 0,015xD | 150 | 0.03 | 0.04 | 0.045 | 0.055 | 0.075 | 0.09 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 6535 HB.

Helix angle = 45°.

Rake angle = 3°.

End face design

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.