<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

S151702R AlCrN

Solid carbide (SC)

Cutting conditions

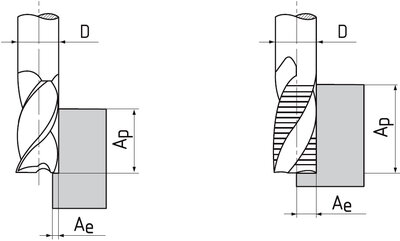

p e c fz (mm/z) Ø 6Ø 8Ø 10Ø 12Ø 16Ø 20

P.1 | Free-cutting steels, general construction steels

≤ 600 N/mm²

2xD

0,06xD

210

0.03

0.04

0.05

0.06

0.08

0.1

P.3 | Tool steels low alloyed

≤ 1100 N/mm²

2xD

0,06xD

175

0.03

0.04

0.05

0.06

0.08

0.1

P.5 | Tool steels high alloyed

≤ 1100 N/mm²

2xD

0,06xD

120

0.03

0.04

0.05

0.06

0.08

0.1

K.1 | Cast iron

< 240 HB

2xD

0,06xD

150

0.03

0.04

0.05

0.06

0.08

0.1

K.2 | Cast iron

> 240 HB

2xD

0,06xD

110

0.03

0.04

0.05

0.06

0.08

0.1

S.1 | Chrome-nickel alloys

≤ 1500 N/mm²

2xD

0,06xD

50

0.03

0.04

0.05

0.06

0.08

0.1

H.1 | Hardened materials

< 54 HRC

2xD

0,06xD

120

0.03

0.04

0.05

0.06

0.08

0.1

H.2 | Hardened materials

54 - 60 HRC

2xD

0,06xD

100

0.03

0.04

0.05

0.06

0.08

0.1

Calculations of cutting conditions

Product attributes

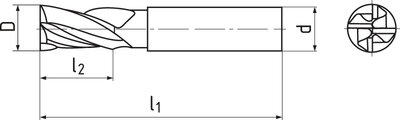

Plain straight shank according to DIN 6535 HA.

Designed for milling (finishing) of materials of medium and higher strength (up to 1200 MPa). Surface roughness Ra 3,2; exceptionally even 1,6.

Feed direction possibility

Oil coolant.

Coating with very high wear resistance and excellent hot hardness.

Company norm

Helix angle = 50/35°.

Rake angle = 6°.

End face design - radius

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

2025 © ZPS-FN a.s. | All right reserved