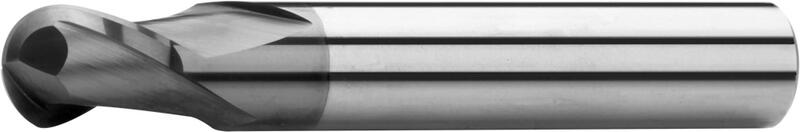

Ball nose end mills short, 2-fluted, type N, plain shank, coating AlTiN

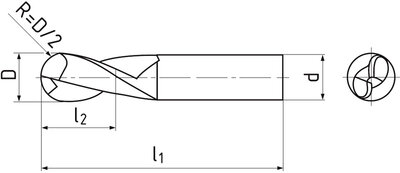

| R |

D

k 12 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|

| 1,5 | 3 | 6 | 50 | 4 | 2 | S510602.030 AlTiN | No |

| 2 | 4 | 6 | 54 | 5 | 2 | S510602.040 AlTiN | Yes |

| 2,5 | 5 | 6 | 54 | 6 | 2 | S510602.050 AlTiN | Yes |

| 3 | 6 | 6 | 54 | 7 | 2 | S510602.060 AlTiN | Yes |

| 4 | 8 | 8 | 58 | 9 | 2 | S510602.080 AlTiN | Yes |

| 5 | 10 | 10 | 66 | 11 | 2 | S510602.100 AlTiN | No |

| 6 | 12 | 12 | 73 | 12 | 2 | S510602.120 AlTiN | Yes |

| 7 | 14 | 14 | 75 | 14 | 2 | S510602.140 AlTiN | No |

| 8 | 16 | 16 | 82 | 16 | 2 | S510602.160 AlTiN | No |

| 9 | 18 | 18 | 84 | 18 | 2 | S510602.180 AlTiN | Yes |

| 10 | 20 | 20 | 92 | 20 | 2 | S510602.200 AlTiN | No |

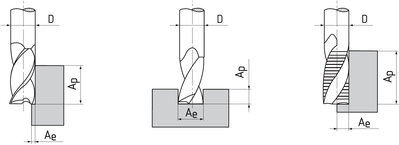

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 0,025xD | 0,05xD | 250 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 0,025xD | 0,05xD | 180 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 0,025xD | 0,05xD | 120 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 0,025xD | 0,05xD | 110 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 0,025xD | 0,05xD | 100 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 0,025xD | 0,05xD | 180 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 0,025xD | 0,05xD | 140 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm² | 0,025xD | 0,05xD | 350 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 0,025xD | 0,05xD | 450 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 0,025xD | 0,05xD | 80 | 0.05 | 0.1 | 0.133 | 0.167 | 0.2 | 0.267 | 0.3 | 0.333 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Helix angle = 30°.

Rake angle = 12°.

Oil coolant.

Offers similar qualities as TiAlN, but even higher hardness. Substanial temperature stability. Designed for the most demanding applications. It provides excellent result mainly when combined with HSSE-PM steels (ASP 2030). The milling cutters manufactured from this steel are coated with AlTiN as standard.