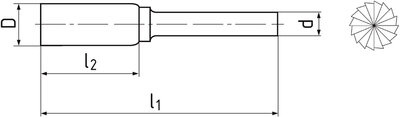

Solid carbide rotary burrs, type ZYA-S, cutting profile MX

| D | d | l1 | l2 | Item code | On stock |

|---|---|---|---|---|---|

| 3 | 3 | 38 | 14 | T1002MX.030 | Yes |

| 6 | 6 | 50 | 16 | T1002MX.060 | Yes |

| 8 | 6 | 65 | 20 | T1002MX.080 | Yes |

| 10 | 6 | 65 | 20 | T1002MX.100 | Yes |

| 12 | 6 | 70 | 25 | T1002MX.120 | Yes |

Cutting conditions

Material |

Strength |

|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² |

| P.2 | General construction steels, steel casting | ≤ 850 N/mm² |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² |

| P.4 | Heat treatable steels | ≤ 900 N/mm² |

| P.5 | Tool steels low alloyed | ≤ 1100 N/mm² |

| P.6 | Tool and treated steels | > 1100 N/mm² |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² |

| N.1 | Aluminium, aluminium cast alloys (Si ≤ 6%) | ≤ 400 N/mm² |

| N.2 | Aluminium cast alloys (Si ≤ 12%) | ≤ 600 N/mm² |

| N.3 | Aluminium cast alloys (Si > 12%) | ≤ 600 N/mm² |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² |

| S.1 | Chrome-nickle alloys | ≤ 1500 N/mm² |

| S.2 | Titanium, titanium cast alloys | ≤ 1250 N/mm² |

Product attributes

Plain straight shank according to DIN 6535 HA.

Feed direction possibility

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

Blade type MX (cross toothing) is a versatile alternative for both soft and hard materials. Its design reduces tool chatter and chip breakage into gritty shapes. These smaller chips also help eliminate groove loading.