Tapper shank end mills long, 30°, type NR

|

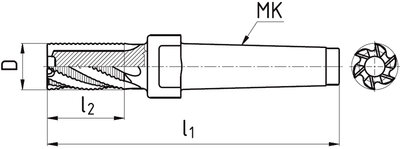

D

k 12 | MK | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 16 | 2 | 148 | 63 | 4 | 425248.160 | Yes |

| 18 | 2 | 148 | 63 | 4 | 425248.180 | Yes |

| 20 | 2 | 160 | 75 | 4 | 425248.200 | Yes |

| 22 | 2 | 160 | 75 | 5 | 425248.220 | Yes |

| 24 | 3 | 192 | 90 | 5 | 425248.240 | Yes |

| 25 | 3 | 192 | 90 | 5 | 425248.250 | Yes |

| 26 | 3 | 192 | 90 | 5 | 425248.260 | Yes |

| 28 | 3 | 192 | 90 | 5 | 425248.280 | Yes |

| 30 | 3 | 192 | 90 | 5 | 425248.300 | Yes |

| 32 | 4 | 254 | 106 | 6 | 425248.320 | Yes |

| 35 | 4 | 254 | 106 | 6 | 425248.350 | Yes |

| 36 | 4 | 254 | 106 | 6 | 425248.360 | No |

| 40 | 4 | 273 | 125 | 6 | 425248.400 | Yes |

| 45 | 4 | 273 | 125 | 6 | 425248.450 | Yes |

| 50 | 5 | 336 | 150 | 8 | 425248.500 | Yes |

| 63 | 5 | 366 | 180 | 8 | 425248.630 | Yes |

Cutting conditions

Material |

Strength |

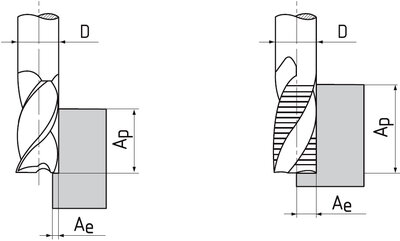

Ap |

Ae |

Vc |

fz(mm/z) Ø 16 |

Ø 20 |

Ø 25 |

Ø 32 |

Ø 40 |

Ø 50 |

Ø 63 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1,5xD | 0,5xD | 45 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 1,5xD | 0,5xD | 39 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1,5xD | 0,5xD | 30 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1,5xD | 0,5xD | 15 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

| K.1 | Cast iron (< 240 HB) | ≤ 820 N/mm² | 1,5xD | 0,5xD | 35 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

| N.4 | Copper-zinc alloys, copper-tin alloys | ≤ 800 N/mm² | 1,5xD | 0,5xD | 80-120 | 0.07 | 0.09 | 0.1 | 0.121 | 0.133 | 0.141 | 0.152 |

Calculations of cutting conditions

Product attributes

Morse taper shank according to DIN 228 A.

For roughing operation and materials of lower and medium strength (up to 700 MPa), surface roughness Ra 12,5 and more.

Feed direction possibility

Morse taper shank acc. to DIN 2207.

Helix angle = 30°.

Rake angle = 12°.

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.