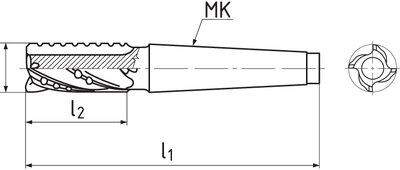

Tapper shank end mills short, semicoarse teeth, 35°, type CB

|

D

js 14 | MK | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 20 | 2 | 123 | 38 | 4 | 422940.200 | Yes |

| 36 | 4 | 178 | 53 | 6 | 422940.360 | Yes |

| 63 | 5 | 241 | 80 | 8 | 422940.630 | Yes |

MK 3 a MK 5 ≠ DIN 845

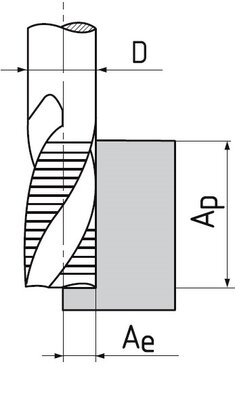

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 20 |

Ø 25 |

Ø 32 |

Ø 40 |

Ø 50 |

Ø 63 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1xD | 0,5xD | 37,5 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 1xD | 0,5xD | 32,5 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1xD | 0,5xD | 25 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1xD | 0,5xD | 22 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

Calculations of cutting conditions

Product attributes

Morse taper shank according to DIN 228 A.

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

Chip Breaker – universal application for roughing.

Helix angle = 35°.

Rake angle = 12°.

High speed steel of average performance, it is applicable especially for cutters of smaller diameters and for milling of materials up to the strength of 900 MPa.