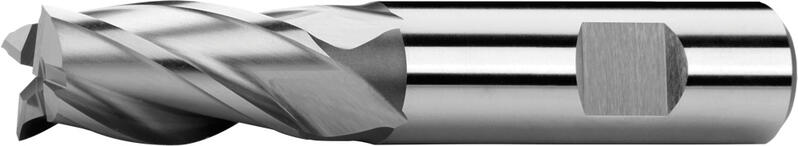

End mills short, 1 tooth cut over centre, 30°, type N, Weldon shank

|

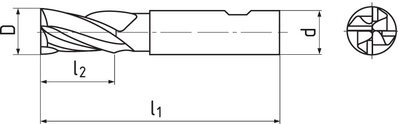

D

k 10 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 2 | 6 | 51 | 7 | 3 | 120518.020 | Yes |

| 2,5 | 6 | 52 | 8 | 3 | 120518.025 | Yes |

| 3 | 6 | 52 | 8 | 4 | 120518.030 | Yes |

| 3,5 | 6 | 54 | 10 | 4 | 120518.035 | Yes |

| 4 | 6 | 55 | 11 | 4 | 120518.040 | Yes |

| 4,5 | 6 | 55 | 11 | 4 | 120518.045 | Yes |

| 5 | 6 | 57 | 13 | 4 | 120518.050 | Yes |

| 5,5 | 6 | 57 | 13 | 4 | 120518.055 | Yes |

| 6 | 6 | 57 | 13 | 4 | 120518.060 | Yes |

| 6,5 | 10 | 66 | 16 | 4 | 120518.065 | Yes |

| 7 | 10 | 66 | 16 | 4 | 120518.070 | Yes |

| 7,5 | 10 | 66 | 16 | 4 | 120518.075 | Yes |

| 8 | 10 | 69 | 19 | 4 | 120518.080 | Yes |

| 8,5 | 10 | 69 | 19 | 4 | 120518.085 | Yes |

| 9 | 10 | 69 | 19 | 4 | 120518.090 | Yes |

| 9,5 | 10 | 69 | 19 | 4 | 120518.095 | Yes |

| 10 | 10 | 72 | 22 | 4 | 120518.100 | Yes |

| 10,5 | 12 | 79 | 22 | 4 | 120518.105 | Yes |

| 11 | 12 | 79 | 26 | 4 | 120518.110 | Yes |

| 12 | 12 | 83 | 26 | 4 | 120518.120 | Yes |

| 13 | 12 | 83 | 26 | 4 | 120518.130 | Yes |

| 14 | 12 | 83 | 26 | 4 | 120518.140 | Yes |

| 15 | 12 | 83 | 26 | 4 | 120518.150 | Yes |

| 16 | 16 | 92 | 32 | 4 | 120518.160 | Yes |

| 17 | 16 | 32 | 92 | 4 | 120518.170 | Yes |

| 18 | 16 | 92 | 32 | 4 | 120518.180 | Yes |

| 20 | 20 | 104 | 38 | 4 | 120518.200 | Yes |

| 21** | 20 | 104 | 38 | 5 | 120518.210 | Yes |

| 22 | 20 | 104 | 38 | 5 | 120518.220 | Yes |

| 24** | 25 | 121 | 45 | 5 | 120518.240 | Yes |

| 25 | 25 | 121 | 45 | 5 | 120518.250 | Yes |

| 26 | 25 | 121 | 45 | 5 | 120518.260 | Yes |

| 28 | 25 | 121 | 45 | 5 | 120518.280 | Yes |

| 30 | 25 | 121 | 45 | 5 | 120518.300 | Yes |

| 32 | 32 | 133 | 53 | 6 | 120518.320 | Yes |

| 35 | 32 | 133 | 53 | 6 | 120518.350 | Yes |

| 36 | 32 | 133 | 53 | 6 | 120518.360 | Yes |

| 40 | 32 | 143 | 63 | 6 | 120518.40032 | Yes |

**) On demand

Cutting conditions

Material |

Strength |

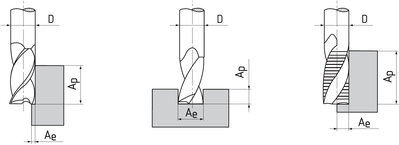

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

Ø 25 |

Ø 32 |

Ø 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1xD | 0,1xD | 45 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 1xD | 0,1xD | 39 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1xD | 0,1xD | 24 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1xD | 0,1xD | 30 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 1xD | 0,1xD | 20 | 0.0042 | 0.0105 | 0.0147 | 0.0196 | 0.0238 | 0.0308 | 0.0357 | 0.0399 | 0.0497 | 0.0637 | 0.077 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1xD | 0,1xD | 15 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1xD | 0,1xD | 35 | 0.006 | 0.015 | 0.021 | 0.028 | 0.034 | 0.044 | 0.051 | 0.057 | 0.071 | 0.091 | 0.11 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 1xD | 0,1xD | 160-300 | 0.0078 | 0.0195 | 0.0273 | 0.0364 | 0.0442 | 0.0572 | 0.0663 | 0.0741 | 0.0923 | 0.1183 | 0.143 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 1xD | 0,1xD | 12 | 0.0042 | 0.0105 | 0.0147 | 0.0196 | 0.0238 | 0.0308 | 0.0357 | 0.0399 | 0.0497 | 0.0637 | 0.077 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 1835 B.

Helix angle = 30°.

Rake angle = 8°.

Feed direction possibility

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.