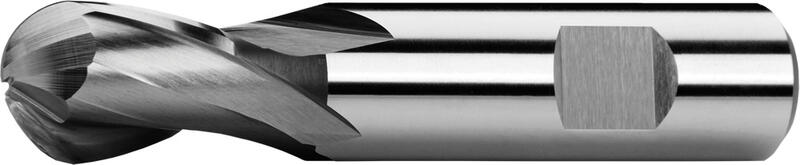

Ball nose end mills short, 2-fluted, 25°, Weldon shank

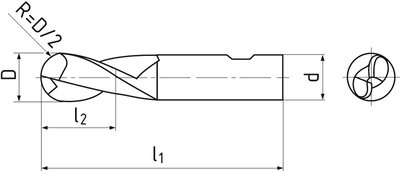

| R |

D

h 10 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|

| 1 | 2 | 6 | 48 | 4 | 2 | 510418.020 | Yes |

| 1,5 | 3 | 6 | 49 | 5 | 2 | 510418.030 | Yes |

| 2 | 4 | 6 | 51 | 7 | 2 | 510418.040 | Yes |

| 2,25 | 4,5 | 6 | 51 | 7 | 2 | 510418.045 | Yes |

| 2,,5 | 5 | 6 | 52 | 8 | 2 | 510418.050 | Yes |

| 3 | 6 | 6 | 52 | 8 | 2 | 510418.060 | Yes |

| 3,5 | 7 | 10 | 60 | 10 | 2 | 510418.070 | Yes |

| 4 | 8 | 10 | 61 | 11 | 2 | 510418.080 | Yes |

| 4,5 | 9 | 10 | 61 | 11 | 2 | 510418.090 | Yes |

| 5 | 10 | 10 | 63 | 13 | 2 | 510418.100 | Yes |

| 5,5 | 11 | 12 | 70 | 13 | 2 | 510418.110 | Yes |

| 6 | 12 | 12 | 73 | 16 | 2 | 510418.120 | Yes |

| 6,5 | 13 | 12 | 73 | 16 | 2 | 510418.130 | Yes |

| 7 | 14 | 12 | 73 | 16 | 2 | 510418.140 | Yes |

| 7,5 | 15 | 12 | 73 | 16 | 2 | 510418.150 | No |

| 8 | 16 | 16 | 79 | 19 | 2 | 510418.160 | Yes |

| 9 | 18 | 16 | 79 | 19 | 2 | 510418.180 | Yes |

| 10 | 20 | 20 | 88 | 22 | 2 | 510418.200 | Yes |

| 11 | 22 | 20 | 88 | 22 | 2 | 510418.220 | Yes |

| 12 | 24 | 25 | 102 | 26 | 2 | 510418.240 | Yes |

| 12,5 | 25 | 25 | 102 | 26 | 2 | 510418.250 | Yes |

| 14 | 28 | 25 | 102 | 26 | 2 | 510418.280 | Yes |

| 15 | 30 | 25 | 102 | 26 | 2 | 510418.300 | Yes |

| 16 | 32 | 32 | 112 | 32 | 2 | 510418.320 | Yes |

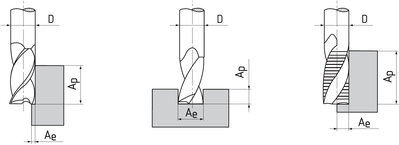

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 0,5xD | 1xD | 39 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 0,5xD | 1xD | 24 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 0,5xD | 1xD | 30 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| P.5 | Heat treatable steels | ≤ 1100 N/mm² | 0,5xD | 1xD | 24 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 0,5xD | 1xD | 20 | 0.0154 | 0.0203 | 0.0252 | 0.0308 | 0.0406 | 0.0455 | 0.0511 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 0,5xD | 1xD | 15 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 0,5xD | 1xD | 25 | 0.022 | 0.029 | 0.036 | 0.044 | 0.058 | 0.065 | 0.073 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 0,5xD | 1xD | 12 | 0.0154 | 0.0203 | 0.0252 | 0.0308 | 0.0406 | 0.0455 | 0.0511 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 1835 B.