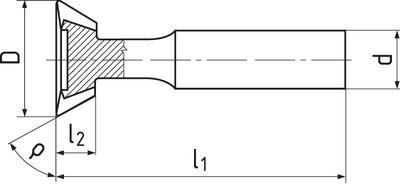

Dovetail milling cutters, plain shank

|

ϱ

±30' |

D

js 16 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|

| 45 | 16 | 12 | 60 | 4 | 10 | 330205.045160 | Yes |

| 45 | 20 | 12 | 63 | 5 | 10 | 330205.045200 | Yes |

| 45 | 25 | 12 | 67 | 6,3 | 10 | 330205.045250 | Yes |

| 45 | 32 | 16 | 71 | 8 | 12 | 330205.045320 | Yes |

| 45 | 40 | 16 | 80 | 10 | 12 | 330205.045400 | Yes |

| 50 | 16 | 12 | 60 | 5 | 10 | 330205.050160 | Yes |

| 50 | 20 | 12 | 63 | 6,3 | 10 | 330205.050200 | Yes |

| 50 | 25 | 12 | 67 | 8 | 10 | 330205.050250 | Yes |

| 55 | 16 | 12 | 60 | 5,6 | 10 | 330205.055160 | Yes |

| 55 | 20 | 12 | 63 | 7,1 | 10 | 330205.055200 | Yes |

| 55 | 25 | 12 | 67 | 9 | 10 | 330205.055250 | Yes |

| 60 | 16 | 12 | 60 | 6,3 | 10 | 330205.060160 | Yes |

| 60 | 20 | 12 | 63 | 8 | 10 | 330205.060200 | Yes |

| 60 | 25 | 12 | 67 | 10 | 10 | 330205.060250 | Yes |

| 60 | 32 | 16 | 71 | 12,5 | 12 | 330205.060320 | Yes |

| 60 | 40 | 16 | 80 | 16 | 12 | 330205.060400 | Yes |

| 70 | 16 | 12 | 60 | 7 | 10 | 330205.070160 | Yes |

| 70 | 20 | 12 | 63 | 9 | 10 | 330205.070200 | Yes |

| 70 | 25 | 16 | 67 | 11 | 10 | 330205.070250 | Yes |

| 75 | 16 | 12 | 60 | 8 | 10 | 330205.075160 | Yes |

| 75 | 25 | 12 | 67 | 10 | 12 | 330205.075250 | Yes |

| 80 | 16 | 12 | 60 | 8 | 10 | 330205.080160 | Yes |

| 80 | 25 | 12 | 67 | 10 | 12 | 330205.080250 | Yes |

| 85 | 16 | 12 | 60 | 8 | 10 | 330205.085160 | Yes |

| 85 | 25 | 12 | 67 | 10 | 12 | 330205.085250 | Yes |

ϱ ≧ 65 ≠ DIN 1833 A

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 16 |

Ø 20 |

Ø 25 |

Ø 32 |

Ø 36 |

Ø 40 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steel, general construction steels | ≤ 600 N/mm² | 1xl2 | t1 (DIN 6888) | 28 | 0.011 | 0.014 | 0.018 | 0.022 | 0.025 | 0.028 |

| P.2 | General construction steels, steel casting | ≤ 850 N/mm² | 1xl2 | t1 (DIN 6888) | 24 | 0.01 | 0.012 | 0.015 | 0.019 | 0.022 | 0.024 |

| P.3 | Tools steels low alloyed | ≤ 1100 N/mm² | 1xl2 | t1 (DIN 6888) | 18 | 0.01 | 0.012 | 0.015 | 0.019 | 0.022 | 0.024 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 1xl2 | t1 (DIN 6888) | 41 | 0.011 | 0.014 | 0.018 | 0.022 | 0.025 | 0.028 |

| S.2 | Titanium, titanium alloys | ≤ 1250 N/mm² | 1xl2 | t1 (DIN 6888) | 9 | 0.007 | 0.08 | 0.011 | 0.013 | 0.015 | 0.017 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 1835 A.

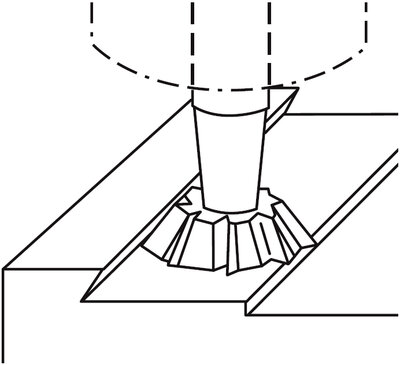

Cutting edges on the face and perimeter of the angle cutter.

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.

Helix angle = 0°.

Rake angle = 0°.