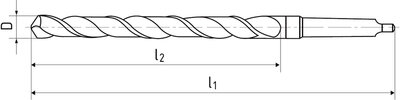

Tapper shank drills, extra long series, type T100

| D | MK | l1 | l2 | Item code | On stock |

|---|---|---|---|---|---|

| 10 | 1 | 285 | 185 | VK70045.1000 | Yes |

| 14 | 1 | 325 | 220 | VK70045.1400 | Yes |

| 15 | 2 | 340 | 220 | VK70045.1500 | No |

| 16 | 2 | 355 | 230 | VK70045.1600 | Yes |

| 19 | 2 | 370 | 245 | VK70045.1900 | No |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 7 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 8 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 7 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 7 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 8 | 0,015 | 0,025 | 0,04 | 0,05 | 0,05 | 0,063 | 0,08 | 0,1 | 0,1 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 6 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² | 8 | 0,01 | 0,02 | 0,032 | 0,04 | 0,04 | 0,05 | 0,063 | 0,08 | 0,08 |

| K.2 | Cast iron(> 240 HB) | > 800 N/mm² | 18 | 0,025 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 45 | 0,03 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 |

| N.3 | Aluminium cast alloys Si (Si > 12%) | ≤ 600 N/mm² | 36 | 0,03 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 18 | 0,015 | 0,025 | 0,04 | 0,05 | 0,05 | 0,063 | 0,08 | 0,1 | 0,1 |

Product attributes

Profile of fluete is wide rounded with rear edges, very thick core, point angle 135°.

Conical lip relief, split point, DIN 1412 form C.

Drilling depth 20xD

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.