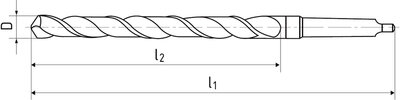

Tapper shank drills, extra long series

| D | MK | l1 | l2 | Item code | On stock |

|---|---|---|---|---|---|

| 8 | 1 | 265 | 165 | VK70010.0800 | Yes |

| 8,5 | 1 | 265 | 165 | VK70010.0850 | Yes |

| 9 | 1 | 275 | 175 | VK70010.0900 | Yes |

| 10 | 1 | 285 | 185 | VK70010.1000 | Yes |

| 11 | 1 | 300 | 195 | VK70010.1100 | Yes |

| 12 | 1 | 310 | 205 | VK70010.1200 | Yes |

| 13 | 1 | 310 | 205 | VK70010.1300 | Yes |

| 13,5 | 1 | 325 | 220 | VK70010.1350 | Yes |

| 14,5 | 2 | 340 | 220 | VK70010.1450 | Yes |

| 15 | 2 | 340 | 220 | VK70010.1500 | Yes |

| 15,5 | 2 | 355 | 230 | VK70010.1550 | Yes |

| 16 | 2 | 355 | 230 | VK70010.1600 | Yes |

| 16,5 | 2 | 355 | 230 | VK70010.1650 | Yes |

| 17 | 2 | 355 | 230 | VK70010.1700 | Yes |

| 17,5 | 2 | 370 | 245 | VK70010.1750 | Yes |

| 18 | 2 | 370 | 245 | VK70010.1800 | Yes |

| 18,5 | 2 | 370 | 245 | VK70010.1850 | Yes |

| 19 | 2 | 370 | 245 | VK70010.1900 | Yes |

| 19,5 | 2 | 385 | 260 | VK70010.1950 | Yes |

| 20 | 2 | 385 | 260 | VK70010.2000 | Yes |

| 20,5 | 2 | 385 | 260 | VK70010.2050 | Yes |

| 21 | 2 | 385 | 260 | VK70010.2100 | Yes |

| 22 | 2 | 405 | 270 | VK70010.2200 | Yes |

| 22,5 | 2 | 405 | 270 | VK70010.2250 | No |

| 23 | 2 | 405 | 270 | VK70010.2300 | Yes |

| 23,5 | 3 | 425 | 270 | VK70010.2350 | No |

| 24 | 3 | 440 | 290 | VK70010.2400 | Yes |

| 24,5 | 3 | 440 | 290 | VK70010.2450 | No |

| 25 | 3 | 440 | 290 | VK70010.2500 | Yes |

| 25,5 | 3 | 440 | 290 | VK70010.2550 | Yes |

| 26 | 3 | 440 | 290 | VK70010.2600 | Yes |

| 26,5 | 3 | 440 | 290 | VK70010.2650 | No |

| 27 | 3 | 460 | 305 | VK70010.2700 | No |

| 28 | 3 | 460 | 305 | VK70010.2800 | Yes |

| 28,5 | 3 | 460 | 305 | VK70010.2850 | No |

| 29 | 3 | 460 | 305 | VK70010.2900 | No |

| 30 | 3 | 460 | 305 | VK70010.3000 | Yes |

| 31 | 3 | 480 | 320 | VK70010.3100 | No |

| 32 | 4 | 505 | 320 | VK70010.3200 | Yes |

| 33 | 4 | 505 | 320 | VK70010.3300 | No |

| 34 | 4 | 530 | 340 | VK70010.3400 | Yes |

| 35 | 4 | 530 | 340 | VK70010.3500 | Yes |

| 36 | 4 | 530 | 340 | VK70010.3600 | No |

| 37 | 4 | 530 | 340 | VK70010.3700 | Yes |

| 38 | 4 | 555 | 360 | VK70010.3800 | No |

| 39 | 4 | 555 | 360 | VK70010.3900 | Yes |

| 40 | 4 | 555 | 360 | VK70010.4000 | Yes |

| 42 | 4 | 555 | 360 | VK70010.4200 | No |

| 43 | 4 | 585 | 385 | VK70010.4300 | No |

| 44 | 4 | 585 | 385 | VK70010.4400 | No |

| 45 | 4 | 585 | 385 | VK70010.4500 | No |

| 47 | 4 | 585 | 385 | VK70010.4700 | No |

| 48 | 4 | 605 | 405 | VK70010.4800 | No |

| 50 | 4 | 605 | 405 | VK70010.5000 | Yes |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 20 | 0,025 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 16 | 0,025 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| K.1 | Cast iron(≤ 240 HB) | ≤ 820 N/mm² | 20 | 0,025 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| K.2 | Cast iron(> 240 HB) | > 800 N/mm² | 16 | 0,025 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 850 N/mm² | 20 | 0,015 | 0,025 | 0,04 | 0,05 | 0,05 | 0,063 | 0,08 | 0,1 | 0,1 |

Product attributes

Designed for steels up to 800 N/mm²

Conical lip relief, split point, DIN 1412 form C.

Point angle 118°

Right helix

Lead of helix 25° - 30°.

Conical lip relief, split point, DIN 1412 form A

Drilling depth 20xD

High speed steel of average performance, it is applicable especially for cutters of smaller diameters and for milling of materials up to the strength of 900 MPa.