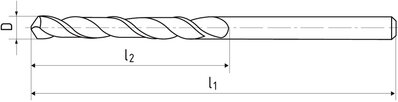

Set of parallel shank twist drills - jobber series, TiN coating

| Item code | On stock |

|---|---|

| VN10010.04 TIN SET | Yes |

| VN10010.05 TIN SET | Yes |

Content of set

| Item code | D | l1 | l2 | VN10010.04 SET-TIN | VN10010.05 SET-TIN |

| VN10010.0100 TIN | 1 | 34 | 12 | • | • |

| VN10010.0150 TIN | 1,5 | 40 | 18 | • | • |

| VN10010.0200 TIN | 2 | 49 | 24 | • | • |

| VN10010.0250 TIN | 2,5 | 57 | 30 | • | • |

| VN10010.0300 TIN | 3 | 61 | 33 | • | • |

| VN10010.0350 TIN | 3,5 | 70 | 39 | • | • |

| VN10010.0400 TIN | 4 | 75 | 43 | • | • |

| VN10010.0450 TIN | 4,5 | 80 | 47 | • | • |

| VN10010.0500 TIN | 5 | 86 | 52 | • | • |

| VN10010.0550 TIN | 5,5 | 93 | 57 | • | • |

| VN10010.0600 TIN | 6 | 93 | 57 | • | • |

| VN10010.0650 TIN | 6,5 | 101 | 63 | • | • |

| VN10010.0700 TIN | 7 | 109 | 69 | • | • |

| VN10010.0750 TIN | 7,5 | 109 | 69 | • | • |

| VN10010.0800 TIN | 8 | 117 | 75 | • | • |

| VN10010.0850 TIN | 8,5 | 117 | 75 | • | • |

| VN10010.0900 TIN | 9 | 125 | 81 | • | • |

| VN10010.0950 TIN | 9,5 | 125 | 81 | • | • |

| VN10010.1000 TIN | 10 | 133 | 87 | • | • |

| VN10010.1050 TIN | 10,5 | 133 | 87 | • | |

| VN10010.1100 TIN | 11 | 142 | 94 | • | |

| VN10010.1150 TIN | 11,5 | 142 | 94 | • | |

| VN10010.1200 TIN | 12 | 151 | 101 | • | |

| VN10010.1250 TIN | 12,5 | 151 | 101 | • | |

| VN10010.1300 TIN | 13 | 151 | 101 | • |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 30 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 22 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| P.3 | Tool steels low alloyed | ≤ 820 N/mm² | 28 | 0,016 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 |

| P.4 | Heat treatable steels | > 800 N/mm² | 22 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| P.5 | Tool steels high alloyed | ≤ 400 N/mm² | 20 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| P.6 | Tool and treated steels | ≤ 820 N/mm² | 18 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| K.1 | Cast iron (≤ 240 HB) | > 800 N/mm² | 33 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| K.2 | Cast iron (> 240 HB) | ≤ 800 N/mm² | 33 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm2 | 33 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

| N.5 | Plastics | ≤ 300 N/mm² | 22 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

Product attributes

Lead of helix 25° - 30°.

Point angle 118°

Right helix

Standard, universal hard layer. In comparison with uncoated tools it provides 300-400% increase in tool life. We recommend cooling.