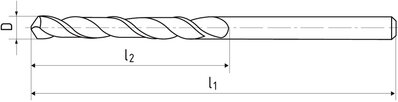

Parallel shank twist drills - jobber series

| D | l1 | l2 | Item code | On stock |

|---|---|---|---|---|

| 0,3 | 19 | 4 | VN10010.0030 | Yes |

| 0,35 | 19 | 4 | VN10010.0035 | No |

| 0,4 | 20 | 5 | VN10010.0040 | Yes |

| 0,45 | 20 | 5 | VN10010.0045 | Yes |

| 0,5 | 22 | 6 | VN10010.0050 | Yes |

| 0,52 | 22 | 6 | VN10010.0052 | No |

| 0,55 | 24 | 7 | VN10010.0055 | Yes |

| 0,6 | 24 | 7 | VN10010.0060 | Yes |

| 0,62 | 26 | 8 | VN10010.0062 | No |

| 0,65 | 26 | 8 | VN10010.0065 | Yes |

| 0,7 | 28 | 9 | VN10010.0070 | Yes |

| 0,72 | 28 | 9 | VN10010.0072 | Yes |

| 0,75 | 28 | 9 | VN10010.0075 | Yes |

| 0,8 | 30 | 10 | VN10010.0080 | No |

| 0,85 | 30 | 10 | VN10010.0085 | Yes |

| 0,9 | 32 | 11 | VN10010.0090 | Yes |

| 0,95 | 32 | 11 | VN10010.0095 | Yes |

| 1 | 34 | 12 | VN10010.0100 | Yes |

| 1,05 | 34 | 12 | VN10010.0105 | Yes |

| 1,1 | 36 | 14 | VN10010.0110 | Yes |

| 1,15 | 36 | 14 | VN10010.0115 | Yes |

| 1,2 | 38 | 16 | VN10010.0120 | Yes |

| 1,25 | 38 | 16 | VN10010.0125 | Yes |

| 1,3 | 38 | 16 | VN10010.0130 | Yes |

| 1,35 | 40 | 18 | VN10010.0135 | Yes |

| 1,4 | 40 | 18 | VN10010.0140 | Yes |

| 1,45 | 40 | 18 | VN10010.0145 | Yes |

| 1,5 | 40 | 18 | VN10010.0150 | Yes |

| 1,55 | 43 | 20 | VN10010.0155 | Yes |

| 1,6 | 43 | 20 | VN10010.0160 | Yes |

| 1,65 | 43 | 20 | VN10010.0165 | Yes |

| 1,7 | 43 | 20 | VN10010.0170 | Yes |

| 1,75 | 46 | 22 | VN10010.0175 | Yes |

| 1,8 | 46 | 22 | VN10010.0180 | Yes |

| 1,85 | 46 | 22 | VN10010.0185 | Yes |

| 1,9 | 46 | 22 | VN10010.0190 | Yes |

| 1,95 | 49 | 24 | VN10010.0195 | Yes |

| 2 | 49 | 24 | VN10010.0200 | Yes |

| 2,05 | 49 | 24 | VN10010.0205 | Yes |

| 2,1 | 49 | 24 | VN10010.0210 | Yes |

| 2,15 | 53 | 27 | VN10010.0215 | Yes |

| 2,2 | 53 | 27 | VN10010.0220 | Yes |

| 2,25 | 53 | 27 | VN10010.0225 | Yes |

| 2,3 | 53 | 27 | VN10010.0230 | Yes |

| 2,35 | 53 | 27 | VN10010.0235 | Yes |

| 2,4 | 57 | 30 | VN10010.0240 | Yes |

| 2,45 | 57 | 30 | VN10010.0245 | Yes |

| 2,5 | 57 | 30 | VN10010.0250 | Yes |

| 2,55 | 57 | 30 | VN10010.0255 | Yes |

| 2,6 | 57 | 30 | VN10010.0260 | Yes |

| 2,65 | 57 | 30 | VN10010.0265 | Yes |

| 2,7 | 61 | 33 | VN10010.0270 | Yes |

| 2,75 | 61 | 33 | VN10010.0275 | Yes |

| 2,8 | 61 | 33 | VN10010.0280 | Yes |

| 2,85 | 61 | 33 | VN10010.0285 | Yes |

| 2,9 | 61 | 33 | VN10010.0290 | Yes |

| 2,95 | 61 | 33 | VN10010.0295 | Yes |

| 3 | 61 | 33 | VN10010.0300 | Yes |

| 3,1 | 65 | 36 | VN10010.0310 | Yes |

| 3,2 | 65 | 36 | VN10010.0320 | Yes |

| 3,3 | 65 | 36 | VN10010.0330 | Yes |

| 3,4 | 70 | 39 | VN10010.0340 | Yes |

| 3,5 | 70 | 39 | VN10010.0350 | Yes |

| 3,6 | 70 | 39 | VN10010.0360 | Yes |

| 3,7 | 70 | 39 | VN10010.0370 | Yes |

| 3,8 | 75 | 43 | VN10010.0380 | Yes |

| 3,9 | 75 | 43 | VN10010.0390 | Yes |

| 4 | 75 | 43 | VN10010.0400 | No |

| 4,1 | 75 | 43 | VN10010.0410 | Yes |

| 4,2 | 75 | 43 | VN10010.0420 | Yes |

| 4,3 | 80 | 47 | VN10010.0430 | Yes |

| 4,4 | 80 | 47 | VN10010.0440 | Yes |

| 4,5 | 80 | 47 | VN10010.0450 | Yes |

| 4,6 | 80 | 47 | VN10010.0460 | Yes |

| 4,7 | 80 | 47 | VN10010.0470 | Yes |

| 4,8 | 86 | 52 | VN10010.0480 | Yes |

| 4,9 | 86 | 52 | VN10010.0490 | Yes |

| 5 | 86 | 52 | VN10010.0500 | Yes |

| 5,1 | 86 | 52 | VN10010.0510 | Yes |

| 5,2 | 86 | 52 | VN10010.0520 | Yes |

| 5,3 | 86 | 52 | VN10010.0530 | Yes |

| 5,4 | 93 | 57 | VN10010.0540 | Yes |

| 5,5 | 93 | 57 | VN10010.0550 | Yes |

| 5,6 | 93 | 57 | VN10010.0560 | Yes |

| 5,7 | 93 | 57 | VN10010.0570 | Yes |

| 5,8 | 93 | 57 | VN10010.0580 | Yes |

| 5,9 | 93 | 57 | VN10010.0590 | Yes |

| 6 | 93 | 57 | VN10010.0600 | Yes |

| 6,1 | 101 | 63 | VN10010.0610 | Yes |

| 6,2 | 101 | 63 | VN10010.0620 | Yes |

| 6,3 | 101 | 63 | VN10010.0630 | Yes |

| 6,4 | 101 | 63 | VN10010.0640 | Yes |

| 6,5 | 101 | 63 | VN10010.0650 | Yes |

| 6,6 | 101 | 63 | VN10010.0660 | No |

| 6,7 | 101 | 63 | VN10010.0670 | Yes |

| 6,8 | 109 | 69 | VN10010.0680 | Yes |

| 6,9 | 109 | 69 | VN10010.0690 | Yes |

| 7 | 109 | 69 | VN10010.0700 | Yes |

| 7,1 | 109 | 69 | VN10010.0710 | Yes |

| 7,2 | 109 | 69 | VN10010.0720 | Yes |

| 7,3 | 109 | 69 | VN10010.0730 | Yes |

| 7,4 | 109 | 69 | VN10010.0740 | Yes |

| 7,5 | 109 | 69 | VN10010.0750 | Yes |

| 7,6 | 117 | 75 | VN10010.0760 | Yes |

| 7,7 | 117 | 75 | VN10010.0770 | Yes |

| 7,8 | 117 | 75 | VN10010.0780 | No |

| 7,9 | 117 | 75 | VN10010.0790 | Yes |

| 8 | 117 | 75 | VN10010.0800 | No |

| 8,1 | 117 | 75 | VN10010.0810 | Yes |

| 8,2 | 117 | 75 | VN10010.0820 | Yes |

| 8,3 | 117 | 75 | VN10010.0830 | No |

| 8,4 | 117 | 75 | VN10010.0840 | No |

| 8,5 | 117 | 75 | VN10010.0850 | Yes |

| 8,6 | 125 | 81 | VN10010.0860 | Yes |

| 8,7 | 125 | 81 | VN10010.0870 | No |

| 8,8 | 125 | 81 | VN10010.0880 | Yes |

| 8,9 | 125 | 81 | VN10010.0890 | Yes |

| 9 | 125 | 81 | VN10010.0900 | Yes |

| 9,1 | 125 | 81 | VN10010.0910 | No |

| 9,2 | 125 | 81 | VN10010.0920 | Yes |

| 9,3 | 125 | 81 | VN10010.0930 | Yes |

| 9,4 | 125 | 81 | VN10010.0940 | Yes |

| 9,5 | 125 | 81 | VN10010.0950 | Yes |

| 9,6 | 133 | 87 | VN10010.0960 | Yes |

| 9,7 | 133 | 87 | VN10010.0970 | Yes |

| 9,8 | 133 | 87 | VN10010.0980 | Yes |

| 9,9 | 133 | 87 | VN10010.0990 | Yes |

| 10 | 133 | 87 | VN10010.1000 | Yes |

| 10,1 | 133 | 87 | VN10010.1010 | Yes |

| 10,2 | 133 | 87 | VN10010.1020 | Yes |

| 10,3 | 133 | 87 | VN10010.1030 | Yes |

| 10,4 | 133 | 87 | VN10010.1040 | No |

| 10,5 | 133 | 87 | VN10010.1050 | Yes |

| 10,6 | 133 | 87 | VN10010.1060 | Yes |

| 10,7 | 142 | 94 | VN10010.1070 | Yes |

| 10,8 | 142 | 94 | VN10010.1080 | Yes |

| 10,9 | 142 | 94 | VN10010.1090 | Yes |

| 11 | 142 | 94 | VN10010.1100 | Yes |

| 11,1 | 142 | 94 | VN10010.1110 | Yes |

| 11,2 | 142 | 94 | VN10010.1120 | Yes |

| 11,3 | 142 | 94 | VN10010.1130 | No |

| 11,4 | 142 | 94 | VN10010.1140 | Yes |

| 11,5 | 142 | 94 | VN10010.1150 | Yes |

| 11,7 | 142 | 94 | VN10010.1170 | Yes |

| 11,8 | 142 | 94 | VN10010.1180 | Yes |

| 11,9 | 151 | 101 | VN10010.1190 | Yes |

| 12 | 151 | 101 | VN10010.1200 | Yes |

| 12,1 | 151 | 101 | VN10010.1210 | Yes |

| 12,2 | 151 | 101 | VN10010.1220 | Yes |

| 12,3 | 151 | 101 | VN10010.1230 | Yes |

| 12,4 | 151 | 101 | VN10010.1240 | Yes |

| 12,5 | 151 | 101 | VN10010.1250 | Yes |

| 12,6 | 151 | 101 | VN10010.1260 | No |

| 12,7 | 151 | 101 | VN10010.1270 | Yes |

| 12,8 | 151 | 101 | VN10010.1280 | Yes |

| 13 | 151 | 101 | VN10010.1300 | Yes |

| 13,1 | 151 | 101 | VN10010.1310 | Yes |

| 13,2 | 151 | 101 | VN10010.1320 | Yes |

| 13,3 | 160 | 108 | VN10010.1330 | Yes |

| 13,4 | 160 | 108 | VN10010.1340 | Yes |

| 13,5 | 160 | 108 | VN10010.1350 | Yes |

| 13,6 | 160 | 108 | VN10010.1360 | Yes |

| 13,7 | 160 | 108 | VN10010.1370 | Yes |

| 13,8 | 160 | 108 | VN10010.1380 | Yes |

| 13,9 | 160 | 108 | VN10010.1390 | Yes |

| 14 | 160 | 108 | VN10010.1400 | Yes |

| 14,5 | 169 | 114 | VN10010.1450 | Yes |

| 14,6 | 169 | 114 | VN10010.1460 | Yes |

| 14,8 | 169 | 114 | VN10010.1480 | Yes |

| 14,9 | 169 | 114 | VN10010.1490 | Yes |

| 15 | 169 | 114 | VN10010.1500 | Yes |

| 15,25 | 178 | 120 | VN10010.1525 | Yes |

| 15,5 | 178 | 120 | VN10010.1550 | Yes |

| 15,75 | 178 | 120 | VN10010.1575 | Yes |

| 16 | 178 | 120 | VN10010.1600 | Yes |

| 16,5 | 184 | 125 | VN10010.1650 | Yes |

| 16,75 | 184 | 125 | VN10010.1675 | Yes |

| 17 | 184 | 125 | VN10010.1700 | No |

| 17,25 | 191 | 130 | VN10010.1725 | Yes |

| 17,5 | 191 | 130 | VN10010.1750 | Yes |

| 18 | 191 | 130 | VN10010.1800 | Yes |

| 18,5 | 198 | 135 | VN10010.1850 | Yes |

| 19 | 198 | 135 | VN10010.1900 | Yes |

| 19,5 | 205 | 140 | VN10010.1950 | Yes |

| 20 | 205 | 140 | VN10010.2000 | Yes |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 30 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 30 | 0,016 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 30 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 25 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 70 | 0,02 | 0,08 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 | 0,315 |

| N.3 | Aluminium cast alloys Si (Si > 12%) | ≤ 600 N/mm² | 36 | 0,016 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 30 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 |

Product attributes

Normal profile of flute, normal core, point angle 118°. Drills made of HSS Co mildly strenghtened core, point angle 130°.

Conical lip relief, split point, DIN 1412 form A

Drilling depth 5xD

High speed steel of average performance, it is applicable especially for cutters of smaller diameters and for milling of materials up to the strength of 900 MPa.