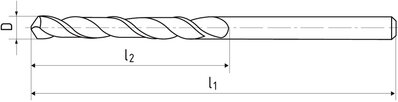

Parallel shank twist drills, jobber series

| D | l1 | l2 | Item code | On stock |

|---|---|---|---|---|

| 3 | 61 | 33 | VN10018.0300 | Yes |

| 3,2 | 65 | 36 | VN10018.0320 | Yes |

| 3,3 | 65 | 36 | VN10018.0330 | Yes |

| 3,5 | 70 | 39 | VN10018.0350 | Yes |

| 4 | 75 | 43 | VN10018.0400 | Yes |

| 4,2 | 75 | 43 | VN10018.0420 | Yes |

| 4,5 | 80 | 47 | VN10018.0450 | Yes |

| 5 | 86 | 52 | VN10018.0500 | Yes |

| 5,1 | 86 | 52 | VN10018.0510 | Yes |

| 5,2 | 86 | 52 | VN10018.0520 | No |

| 5,5 | 93 | 57 | VN10018.0550 | No |

| 6 | 93 | 57 | VN10018.0600 | Yes |

| 6,5 | 101 | 63 | VN10018.0650 | Yes |

| 6,8 | 109 | 69 | VN10018.0680 | Yes |

| 7 | 109 | 69 | VN10018.0700 | Yes |

| 7,5 | 109 | 69 | VN10018.0750 | Yes |

| 8 | 117 | 75 | VN10018.0800 | Yes |

| 8,5 | 117 | 75 | VN10018.0850 | No |

| 9 | 125 | 81 | VN10018.0900 | Yes |

| 9,5 | 125 | 81 | VN10018.0950 | Yes |

| 10 | 133 | 87 | VN10018.1000 | No |

| 10,5 | 133 | 87 | VN10018.1050 | Yes |

| 11 | 142 | 94 | VN10018.1100 | Yes |

| 11,5 | 142 | 94 | VN10018.1150 | Yes |

| 12 | 151 | 101 | VN10018.1200 | Yes |

| 12,5 | 151 | 101 | VN10018.1250 | No |

| 13 | 151 | 101 | VN10018.1300 | Yes |

| 13,5 | 160 | 108 | VN10018.1350 | Yes |

| 14 | 160 | 108 | VN10018.1400 | Yes |

| 14,5 | 169 | 114 | VN10018.1450 | Yes |

| 15 | 169 | 114 | VN10018.1500 | Yes |

| 16 | 178 | 120 | VN10018.1600 | Yes |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

Ø16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 40 | 0,016 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 40 | 0,016 | 0,05 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 20 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 18 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,1 | 0,2 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 14 | 0,012 | 0,032 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,2 |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² | 16 | 0,012 | 0,032 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 35 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 30 | 0,018 | 0,063 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 35 | 0,014 | 0,04 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 |

Product attributes

Normal profile of flute, normal core, point angle 118°. Drills made of HSS Co mildly strenghtened core, point angle 130°.

Conical lip relief, split point, DIN 1412 form C.

Drilling depth 5xD

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.