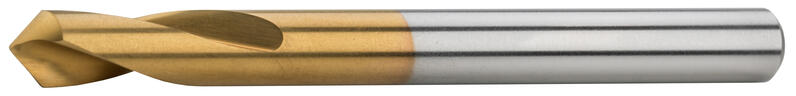

NC-spotting drills 90°, coating TiN

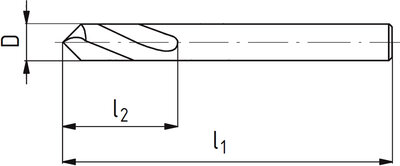

| D | l1 | l2 | Item code | On stock |

|---|---|---|---|---|

| 3 | 50 | 10 | VN50105.0300 TiN | Yes |

| 4 | 52 | 12 | VN50105.0400 TiN | Yes |

| 5 | 60 | 15 | VN50105.0500 TiN | Yes |

| 6 | 66 | 20 | VN50105.0600 TiN | Yes |

| 8 | 79 | 25 | VN50105.0800 TiN | Yes |

| 10 | 89 | 25 | VN50105.1000 TiN | Yes |

| 12 | 102 | 30 | VN50105.1200 TiN | Yes |

| 14 | 115 | 35 | VN50105.1400 TiN | No |

| 16 | 115 | 35 | VN50105.1600 TiN | Yes |

| 20 | 131 | 40 | VN50105.2000 TiN | Yes |

| 25 | 138 | 45 | VN50105.2500 TiN | Yes |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

Ø16 |

Ø20 |

Ø25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 35 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 33 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 28 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 22 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 20 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 18 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 12 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 12 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² | 8 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| K.1 | Cast iron | ≤ 820 N/mm² (≤ 240 HB) | 33 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| K.2 | Cast iron | > 800 N/mm² (> 240 HB) | 33 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| N.3 | Aluminium cast alloys Si (Si > 12%) | ≤ 600 N/mm² | 60 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 65 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| N.5 | Plastics | ≤ 300 N/mm² | 36 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

Product attributes

Lead of helix 20°.

Point angle 90°

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.