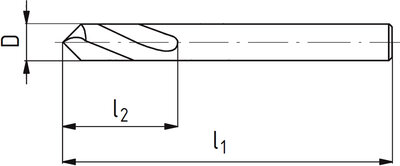

NC-spotting drills 120°, coating TiN

| D | l1 | l2 | Item code | On stock |

|---|---|---|---|---|

| 3 | 50 | 10 | VN50115.0300 TiN | Yes |

| 4 | 52 | 12 | VN50115.0400 TiN | Yes |

| 5 | 60 | 15 | VN50115.0500 TiN | Yes |

| 6 | 66 | 20 | VN50115.0600 TiN | Yes |

| 8 | 79 | 25 | VN50115.0800 TiN | Yes |

| 10 | 89 | 25 | VN50115.1000 TiN | Yes |

| 12 | 102 | 30 | VN50115.1200 TiN | Yes |

| 14 | 115 | 35 | VN50115.1400 TiN | Yes |

| 16 | 115 | 35 | VN50115.1600 TiN | Yes |

| 20 | 131 | 40 | VN50115.2000 TiN | No |

| 25 | 138 | 45 | VN50115.2500 TiN | No |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

Ø16 |

Ø20 |

Ø25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 35 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 33 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 28 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 22 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 20 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 18 | 0,063 | 0,08 | 0,08 | 0,1 | 0,125 | 0,16 | 0,16 | 0,2 | 0,25 | 0,315 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 12 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 12 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² | 8 | 0,05 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 |

| K.1 | Cast iron | ≤ 820 N/mm² (≤ 240 HB) | 33 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| K.2 | Cast iron | > 800 N/mm² (> 240 HB) | 33 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| N.3 | Aluminium cast alloys Si (Si > 12%) | ≤ 600 N/mm² | 60 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 | 0,5 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 65 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

| N.5 | Plastics | ≤ 300 N/mm² | 36 | 0,08 | 0,1 | 0,1 | 0,125 | 0,16 | 0,2 | 0,2 | 0,25 | 0,315 | 0,4 |

Calculations of cutting conditions

Product attributes

Universal usage. Suitable for materials up to strength 900 MPa.

Conical lip relief, DIN 1412 form N.

Right helix

Standard, universal hard layer. In comparison with uncoated tools it provides 300-400% increase in tool life. We recommend cooling.