<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

VN40090

High-speed steel HSS

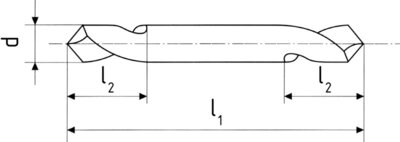

D

l1

l2

Item code

On stock

2,5

43

9,5

VN40090.0250

Yes

2,6

43

9,5

VN40090.0260

No

2,8

46

10,6

VN40090.0280

No

3

46

10,6

VN40090.0300

Yes

3,1

49

11,2

VN40090.0310

No

3,2

49

11,2

VN40090.0320

Yes

3,3

49

11,2

VN40090.0330

No

3,4

52

12,5

VN40090.0340

No

3,5

52

12,5

VN40090.0350

Yes

3,7

52

12,5

VN40090.0370

No

4

55

14

VN40090.0400

Yes

4,1

55

14

VN40090.0410

Yes

4,2

55

14

VN40090.0420

Yes

4,3

58

15,5

VN40090.0430

No

4,5

58

15,5

VN40090.0450

No

4,8

62

19

VN40090.0480

No

4,9

62

19

VN40090.0490

Yes

5

62

19

VN40090.0500

Yes

5,1

62

19

VN40090.0510

No

5,2

62

19

VN40090.0520

Yes

5,5

66

24

VN40090.0550

No

5,6

66

24

VN40090.0560

No

6

66

24

VN40090.0600

Yes

6,1

70

24

VN40090.0610

No

6,2

70

24

VN40090.0620

No

6,4

70

24

VN40090.0640

No

6,5

70

24

VN40090.0650

Yes

6,8

74

24

VN40090.0680

No

7

74

24

VN40090.0700

Yes

8

79

25

VN40090.0800

Yes

8,5

79

25

VN40090.0850

No

10

89

25

VN40090.1000

Yes

Cutting conditions

P.1 | Free-cutting steels, general construction steels

≤ 600 N/mm²

P.2 | General construction steels, steel castings

≤ 850 N/mm²

N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%)

≤ 400 N/mm²

N.2 | Aluminium cast alloys Si (Si ≤ 12%)

≤ 600 N/mm²

N.3 | Aluminium cast alloys Si (Si > 12%)

≤ 600 N/mm²

N.4 | Cooper-zinc alloys, cooper-tin alloys

≤ 800 N/mm²

Calculations of cutting conditions

Product attributes

Point angle 118°

Conical lip relief, split point, DIN 1412 form C.

High speed steel of average performance, it is applicable especially for cutters of smaller diameters and for milling of materials up to the strength of 900 MPa.

2025 © ZPS-FN a.s. | All right reserved