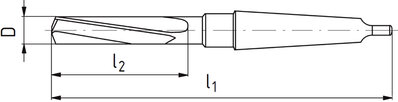

Tapper shank drills for hard machined materials, pasivation

| D | MK | l1 | l2 | Item code | On stock |

|---|---|---|---|---|---|

| 10 | 2 | 190 | 90 | VK10028.1000 | Yes |

| 11 | 2 | 190 | 90 | VK10028.1100 | Yes |

| 12 | 2 | 190 | 90 | VK10028.1200 | Yes |

| 13 | 2 | 190 | 90 | VK10028.1300 | Yes |

| 14 | 2 | 190 | 90 | VK10028.1400 | Yes |

| 15 | 2 | 190 | 90 | VK10028.1500 | Yes |

| 16 | 2 | 190 | 90 | VK10028.1600 | No |

| 17 | 2 | 190 | 90 | VK10028.1700 | Yes |

| 18 | 2 | 190 | 90 | VK10028.1800 | Yes |

| 19 | 3 | 225 | 105 | VK10028.1900 | No |

| 20 | 3 | 225 | 105 | VK10028.2000 | Yes |

| 21 | 3 | 225 | 105 | VK10028.2100 | Yes |

| 22 | 3 | 225 | 105 | VK10028.2200 | Yes |

| 23 | 3 | 225 | 105 | VK10028.2300 | Yes |

| 24 | 3 | 225 | 105 | VK10028.2400 | Yes |

| 25 | 3 | 225 | 105 | VK10028.2500 | No |

| 26 | 3 | 225 | 105 | VK10028.2600 | Yes |

| 27 | 4 | 265 | 120 | VK10028.2700 | Yes |

| 28 | 4 | 265 | 120 | VK10028.2800 | Yes |

| 29 | 4 | 265 | 120 | VK10028.2900 | Yes |

| 30 | 4 | 265 | 120 | VK10028.3000 | Yes |

| 31 | 4 | 265 | 120 | VK10028.3100 | Yes |

| 32 | 4 | 265 | 120 | VK10028.3200 | Yes |

| 33 | 4 | 265 | 120 | VK10028.3300 | Yes |

| 34 | 4 | 265 | 120 | VK10028.3400 | Yes |

| 35 | 4 | 265 | 120 | VK10028.3500 | No |

| 36 | 4 | 265 | 120 | VK10028.3600 | Yes |

| 37 | 4 | 265 | 120 | VK10028.3700 | No |

| 38 | 4 | 265 | 120 | VK10028.3800 | Yes |

| 39 | 4 | 265 | 120 | VK10028.3900 | Yes |

| 40 | 4 | 265 | 120 | VK10028.4000 | Yes |

| 41 | 4 | 265 | 120 | VK10028.4100 | No |

| 42 | 4 | 265 | 120 | VK10028.4200 | No |

| 43 | 4 | 265 | 120 | VK10028.4300 | No |

| 44 | 4 | 265 | 120 | VK10028.4400 | No |

| 45 | 4 | 265 | 102 | VK10028.4500 | No |

| 50 | 5 | 340 | 150 | VK10028.5000 | No |

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r) Ø10 |

Ø12,5 |

Ø16 |

Ø20 |

Ø25 |

Ø31,5 |

Ø40 |

Ø50 |

|---|---|---|---|---|---|---|---|---|---|---|

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 6 | 0,063 | 0,063 | 0,08 | 0,1 | 0,125 | 0,125 | 0,16 | 0,2 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² (<54 HRC) | 9 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 |

| H.2 | Hardened materials (54 - 60 HRC) | 1920 - 2210 N/mm² (54 - 60 HRC) | 5 | 0,125 | 0,125 | 0,16 | 0,2 | 0,25 | 0,25 | 0,315 | 0,4 |

Product attributes

Normal profile of flute, normal core, point angle 118°. Drills made of HSS Co mildly strenghtened core, point angle 130°.

Conical lip relief, split point, DIN 1412 form C.

Drilling depth 5xD

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.

Lead of helix 10° - 15°.

Point angle 128°

Right helix

Steamtempered (Black finish) is a process where a layer of iron oxide is formed on the surface of the tool. This layer increases the abrasion resistance of the blade, increases corrosion resistance and improves lubrication of the tool. The most effective use is for drill bits and taps.