Solid carbide drills with coolant holes, 5xD, coating AlTiN

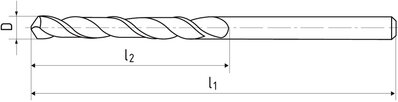

| D | d | l1 | l2 | Item code | On stock |

|---|---|---|---|---|---|

| 3,4 | 6 | 66 | 28 | S10122.034 | Yes |

| 3,5 | 6 | 66 | 28 | S10122.035 | Yes |

| 3,7 | 6 | 66 | 28 | S10122.037 | Yes |

| 4,1 | 6 | 74 | 36 | S10122.041 | Yes |

| 5,5 | 6 | 82 | 44 | S10122.055 | Yes |

| 5,6 | 6 | 82 | 44 | S10122.056 | Yes |

| 5,9 | 6 | 82 | 44 | S10122.059 | Yes |

| 7 | 8 | 91 | 53 | S10122.070 | Yes |

| 7,2 | 8 | 91 | 53 | S10122.072 | Yes |

| 8,2 | 10 | 103 | 61 | S10122.082 | Yes |

| 8,3 | 10 | 103 | 61 | S10122.083 | Yes |

| 8,4 | 10 | 103 | 61 | S10122.084 | Yes |

| 8,8 | 10 | 103 | 61 | S10122.088 | Yes |

| 9,1 | 10 | 103 | 61 | S10122.091 | Yes |

| 9,2 | 10 | 103 | 61 | S10122.092 | Yes |

| 9,3 | 10 | 103 | 61 | S10122.093 | Yes |

| 9,9 | 10 | 103 | 61 | S10122.099 | Yes |

| 11,2 | 12 | 118 | 71 | S10122.112 | Yes |

| 11,5 | 12 | 118 | 71 | S10122.115 | Yes |

| 11,8 | 12 | 118 | 71 | S10122.118 | No |

| 17 | 18 | 143 | 93 | S10122.170 | Yes |

| 19,5 | 20 | 153 | 101 | S10122.195 | Yes |

Cutting conditions

Material |

Strength |

|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² |

| P.4 | Heat treatable steels | ≤ 900 N/mm² |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² |

Product attributes

Plain straight shank according to DIN 6535 HA.

Point angle 140°

With coolant holes

Offers similar qualities as TiAlN, but even higher hardness. Substanial temperature stability. Designed for the most demanding applications. It provides excellent result mainly when combined with HSSE-PM steels (ASP 2030). The milling cutters manufactured from this steel are coated with AlTiN as standard.

Normal profile of flute, normal core, point angle 118°. Drills made of HSS Co mildly strenghtened core, point angle 130°.

Drilling depth 5xD

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.