<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

Home Catalogue Solid carbide drills with coolant holes, 5xD, coating AlTiN

S10222 AlTiN

Solid carbide (SC)

DIN 6537L

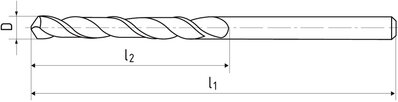

D

l1

l2

Item code

On stock

1

55

10

S10222.010 AlTiN

No

1,1

55

12

S10222.011 AlTiN

No

1,2

55

12

S10222.012 AlTiN

No

1,3

55

12

S10222.013 AlTiN

No

1,4

55

12

S10222.014 AlTiN

No

1,5

55

12

S10222.015 AlTiN

No

1,6

55

16

S10222.016 AlTiN

No

1,7

55

16

S10222.017 AlTiN

No

1,8

55

16

S10222.018 AlTiN

No

1,9

55

16

S10222.019 AlTiN

No

2

57

21

S10222.020 AlTiN

Yes

2,1

57

21

S10222.021 AlTiN

No

2,2

57

21

S10222.022 AlTiN

No

2,3

57

21

S10222.023 AlTiN

No

2,4

57

21

S10222.024 AlTiN

No

2,5

57

21

S10222.025 AlTiN

Yes

2,6

57

21

S10222.026 AlTiN

No

2,7

57

21

S10222.027 AlTiN

No

2,8

57

21

S10222.028 AlTiN

No

2,9

57

21

S10222.029 AlTiN

No

3

66

28

S10222.030 AlTiN

No

3,1

66

28

S10222.031 AlTiN

No

3,2

66

28

S10222.032 AlTiN

Yes

3,3

66

28

S10222.033 AlTiN

Yes

3,4

66

28

S10222.034 AlTiN

Yes

3,5

66

28

S10222.035 AlTiN

Yes

3,6

66

28

S10222.036 AlTiN

No

3,7

66

28

S10222.037 AlTiN

Yes

3,8

74

36

S10222.038 AlTiN

No

3,9

74

36

S10222.039 AlTiN

No

4

74

36

S10222.040 AlTiN

Yes

4,1

74

36

S10222.041 AlTiN

No

4,2

74

36

S10222.042 AlTiN

Yes

4,3

74

36

S10222.043 AlTiN

No

4,4

74

36

S10222.044 AlTiN

No

4,5

74

36

S10222.045 AlTiN

Yes

4,6

74

36

S10222.046 AlTiN

No

4,7

74

36

S10222.047 AlTiN

Yes

4,8

82

44

S10222.048 AlTiN

Yes

4,9

82

44

S10222.049 AlTiN

No

5

82

44

S10222.050 AlTiN

Yes

5,1

82

44

S10222.051 AlTiN

No

5,2

82

44

S10222.052 AlTiN

No

5,3

82

44

S10222.053 AlTiN

No

5,4

82

44

S10222.054 AlTiN

No

5,5

82

44

S10222.055 AlTiN

Yes

5,6

82

44

S10222.056 AlTiN

Yes

5,7

82

44

S10222.057 AlTiN

No

5,8

82

44

S10222.058 AlTiN

No

5,9

82

44

S10222.059 AlTiN

No

6

82

44

S10222.060 AlTiN

Yes

6,1

91

53

S10222.061 AlTiN

No

6,2

92

53

S10222.062 AlTiN

Yes

6,3

91

53

S10222.063 AlTiN

No

6,4

91

53

S10222.064 AlTiN

No

6,5

91

53

S10222.065 AlTiN

Yes

6,6

91

53

S10222.066 AlTiN

No

6,7

91

53

S10222.067 AlTiN

No

6,8

91

53

S10222.068 AlTiN

Yes

6,9

91

53

S10222.069 AlTiN

No

7

91

53

S10222.070 AlTiN

Yes

7,1

91

53

S10222.071 AlTiN

No

7,2

91

53

S10222.072 AlTiN

No

7,3

91

53

S10222.073 AlTiN

No

7,4

91

53

S10222.074 AlTiN

Yes

7,5

91

53

S10222.075 AlTiN

No

7,6

91

53

S10222.076 AlTiN

No

7,7

91

53

S10222.077 AlTiN

No

7,8

91

53

S10222.078 AlTiN

Yes

7,9

91

53

S10222.079 AlTiN

No

8

91

53

S10222.080 AlTiN

Yes

8,1

103

61

S10222.081 AlTiN

No

8,2

103

61

S10222.082 AlTiN

No

8,3

103

61

S10222.083 AlTiN

No

8,4

103

61

S10222.084 AlTiN

No

8,5

103

61

S10222.085 AlTiN

Yes

8,6

103

61

S10222.086 AlTiN

No

8,7

103

61

S10222.087 AlTiN

Yes

8,8

103

61

S10222.088 AlTiN

No

8,9

103

61

S10222.089 AlTiN

No

9

103

61

S10222.090 AlTiN

Yes

9,1

103

61

S10222.091 AlTiN

No

9,2

103

61

S10222.092 AlTiN

No

9,3

103

61

S10222.093 AlTiN

No

9,4

103

61

S10222.094 AlTiN

No

9,5

103

61

S10222.095 AlTiN

Yes

9,6

103

61

S10222.096 AlTiN

Yes

9,7

103

61

S10222.097 AlTiN

No

9,8

103

61

S10222.098 AlTiN

No

9,9

103

61

S10222.099 AlTiN

No

10

103

61

S10222.100 AlTiN

Yes

10,1

118

71

S10222.101 AlTiN

No

10,2

118

71

S10222.102 AlTiN

No

10,3

118

71

S10222.103 AlTiN

No

10,4

118

71

S10222.104 AlTiN

No

10,5

118

71

S10222.105 AlTiN

Yes

10,6

118

71

S10222.106 AlTiN

No

10,7

118

71

S10222.107 AlTiN

No

10,8

118

71

S10222.108 AlTiN

No

10,9

118

71

S10222.109 AlTiN

No

11

118

71

S10222.110 AlTiN

Yes

11,1

118

71

S10222.111 AlTiN

No

11,2

118

71

S10222.112 AlTiN

No

11,3

118

71

S10222.113 AlTiN

No

11,4

118

71

S10222.114 AlTiN

No

11,5

118

71

S10222.115 AlTiN

Yes

11,6

118

71

S10222.116 AlTiN

No

11,7

118

71

S10222.117 AlTiN

No

11,8

118

71

S10222.118 AlTiN

No

11,9

118

71

S10222.119 AlTiN

No

12

118

71

S10222.120 AlTiN

Yes

12,2

124

77

S10222.122 AlTiN

No

12,3

124

77

S10222.123 AlTiN

No

12,5

124

77

S10222.125 AlTiN

Yes

12,8

124

77

S10222.128 AlTiN

No

13

124

77

S10222.130 AlTiN

Yes

13,2

124

77

S10222.132 AlTiN

No

13,5

124

77

S10222.135 AlTiN

No

13,7

124

77

S10222.137 AlTiN

No

13,8

124

77

S10222.138 AlTiN

No

14

124

77

S10222.140 AlTiN

Yes

14,2

133

83

S10222.142 AlTiN

No

14,5

133

83

S10222.145 AlTiN

No

14,8

133

83

S10222.148 AlTiN

No

15

133

83

S10222.150 AlTiN

Yes

15,1

133

83

S10222.151 AlTiN

No

15,2

133

83

S10222.152 AlTiN

No

15,5

133

83

S10222.155 AlTiN

No

15,8

133

83

S10222.158 AlTiN

No

16

133

83

S10222.160 AlTiN

Yes

16,5

143

93

S10222.165 AlTiN

No

16,8

143

93

S10222.168 AlTiN

No

17

143

93

S10222.170 AlTiN

No

17,5

143

93

S10222.175 AlTiN

No

17,8

143

93

S10222.178 AlTiN

No

18

143

93

S10222.180 AlTiN

No

18,5

153

101

S10222.185 AlTiN

No

19

153

101

S10222.190 AlTiN

No

19,5

153

101

S10222.195 AlTiN

No

20

153

101

S10222.200 AlTiN

No

Cutting conditions

P.1 | Free-cutting steels, general construction steels

≤ 600 N/mm²

P.2 | General construction steels, steel castings

≤ 850 N/mm²

P.4 | Heat treatable steels

≤ 900 N/mm²

M.1 | Corrosion- and acid-proof steels

≤ 750 N/mm²

M.3 | Corrosion- and acid-proof steels

> 850 N/mm²

K.1 | Cast iron (≤ 240 HB)

≤ 820 N/mm²

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Point angle 140°

With coolant holes

Offers similar qualities as TiAlN, but even higher hardness. Substanial temperature stability. Designed for the most demanding applications. It provides excellent result mainly when combined with HSSE-PM steels (ASP 2030). The milling cutters manufactured from this steel are coated with AlTiN as standard.

Universal usage. Suitable for materials up to strength 900 MPa.

Drilling depth 5xD

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

2025 © ZPS-FN a.s. | All right reserved