Shell end mills, semicoarse teeth, type NR, coating TiAlN

|

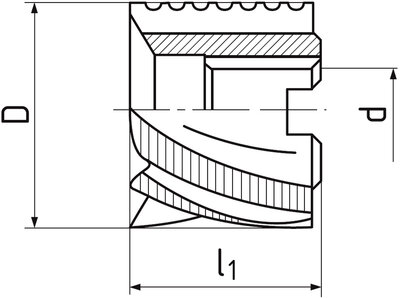

D

js 16 |

d

H 7 | l1 | Z | Item code | On stock |

|---|---|---|---|---|---|

| 40 | 16 | 32 | 6 | 624278V.040 TiAlN | Yes |

| 50 | 22 | 36 | 6 | 624278V.050 TiAlN | Yes |

| 63 | 27 | 40 | 8 | 624278V.063 TiAlN | Yes |

| 80 | 27 | 45 | 8 | 624278V.080 TiAlN | Yes |

| 100 | 32 | 50 | 10 | 624278V.100 TiAlN | Yes |

| 125 | 40 | 56 | 12 | 624278V.125 TiAlN | No |

| 160 | 50 | 63 | 14 | 624278V.160 TiAlN | No |

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 40 |

Ø 50 |

Ø 63 |

Ø 80 |

Ø 100 |

Ø 125 |

Ø 160 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 0,8xl1 | 0,75xD | 67,5 | 0.096 | 0.102 | 0.12 | 0.132 | 0.138 | 0.14 | 0.144 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 0,8xl1 | 0,75xD | 58,5 | 0.096 | 0.102 | 0.12 | 0.132 | 0.138 | 0.14 | 0.144 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 0,8xl1 | 0,75xD | 45 | 0.096 | 0.102 | 0.12 | 0.132 | 0.138 | 0.14 | 0.144 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 0,8xl1 | 0,75xD | 22,5 | 0.096 | 0.102 | 0.12 | 0.132 | 0.138 | 0.14 | 0.144 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 0,8xl1 | 0,75xD | 37,5 | 0.096 | 0.102 | 0.12 | 0.132 | 0.138 | 0.14 | 0.144 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 0,8xl1 | 0,75xD | 18 | 0.067 | 0.071 | 0.084 | 0.092 | 0.097 | 0.098 | 0.101 |

Calculations of cutting conditions

Product attributes

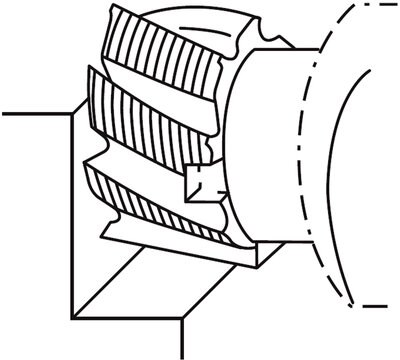

Straight bore with standard keyway and driving slot according to DIN 138.

Helix angle = 30°.

Rake angle = 12°.

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.

For roughing operation and materials of lower and medium strength (up to 700 MPa), surface roughness Ra 12,5 and more.

Feed direction possibility

Its advantage is in high hardness in higher temperaures, good oxidation resistance and low temperature conductivity. Universal usage with emphasis on high-speed miling without cooling. Siutable for milling of hard materials.