<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

- Home

- Catalogue

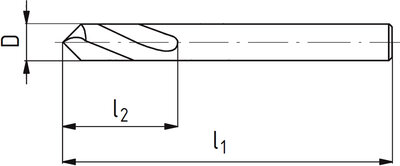

- NC-spotting drills 120°, code VN50115, diameter 20 mm

VN50115.2000

High-speed steel HSS Co5

Cutting conditions

Material |

Strength |

Vc |

fz(mm/r)

Ø1 |

Ø2 |

Ø3,15 |

Ø4 |

Ø5 |

Ø6,3 |

Ø8 |

Ø10 |

Ø12,5 |

| P.1 | Free-cutting steels, general construction steels |

≤ 600 N/mm² |

40 |

0,016 |

0,05 |

0,08 |

0,1 |

0,1 |

0,125 |

0,16 |

0,2 |

0,2 |

| P.2 | General construction steels, steel castings |

≤ 850 N/mm² |

40 |

0,016 |

0,05 |

0,08 |

0,1 |

0,1 |

0,125 |

0,16 |

0,2 |

0,2 |

| P.3 | Tool steels low alloyed |

≤ 1100 N/mm² |

35 |

0,016 |

0,05 |

0,08 |

0,1 |

0,1 |

0,125 |

0,16 |

0,2 |

0,2 |

| P.4 | Heat treatable steels |

≤ 900 N/mm2 |

22 |

0,014 |

0,04 |

0,063 |

0,08 |

0,08 |

0,1 |

0,125 |

0,16 |

0,16 |

| M.1 | Corrosion- and acid-proof steels |

≤ 750 N/mm² |

12 |

0,012 |

0,032 |

0,05 |

0,063 |

0,063 |

0,08 |

0,1 |

0,125 |

0,125 |

| M.2 | Corrosion- and acid-proof steels |

750 - 850 N/mm² |

10 |

0,012 |

0,032 |

0,05 |

0,063 |

0,063 |

0,08 |

0,1 |

0,125 |

0,125 |

| M.3 | Corrosion- and acid-proof steels |

> 850 N/mm² |

10 |

0,012 |

0,032 |

0,05 |

0,063 |

0,063 |

0,08 |

0,1 |

0,125 |

0,125 |

| K.1 | Cast iron (≤ 240 HB) |

≤ 820 N/mm² |

33 |

0,018 |

0,063 |

0,1 |

0,125 |

0,125 |

0,16 |

0,2 |

0,25 |

0,25 |

| K.2 | Cast iron (> 240 HB) |

> 800 N/mm² |

30 |

0,018 |

0,063 |

0,1 |

0,125 |

0,125 |

0,16 |

0,2 |

0,25 |

0,25 |

| S.1 | Chrome-nickel alloysi |

≤ 1500 N/mm² |

6 |

0,006 |

0,02 |

0,032 |

0,04 |

0,04 |

0,05 |

0,063 |

0,08 |

0,08 |

Calculations of cutting conditions

Product attributes

Universal usage. Suitable for materials up to strength 900 MPa.

Conical lip relief, DIN 1412 form N.

Right helix

Point angle 120°

Very high performance high speed steel with good toughness for milling cutters and for milling of materials up to the strength of 1200 MPa.

2026 © ZPS-FN a.s. | All right reserved