End mills long with corner radius, 44°-45°, type N, Weldon shank, coating AlCrN

|

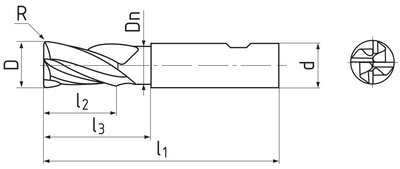

D

e 8 |

d

h 5 | l1 | l2 | l3 | Dn | R | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|---|---|

| 4 | 6 | 57 | 5 | 16 | 3,6 | 0,3 | 4 | S152512R.04003 AlCrN | No |

| 4 | 6 | 57 | 5 | 16 | 3,6 | 0,5 | 4 | S152512R.04005 AlCrN | No |

| 6 | 6 | 62 | 7 | 24 | 5,4 | 0,3 | 4 | S152512R.06003 AlCrN | No |

| 6 | 6 | 62 | 7 | 24 | 5,4 | 0,5 | 4 | S152512R.06005 AlCrN | No |

| 6 | 6 | 62 | 7 | 24 | 5,4 | 1 | 4 | S152512R.06010 AlCrN | No |

| 8 | 8 | 68 | 9 | 30 | 7,2 | 0,5 | 4 | S152512R.08005 AlCrN | No |

| 8 | 8 | 68 | 9 | 30 | 7,2 | 1 | 4 | S152512R.08010 AlCrN | No |

| 10 | 10 | 80 | 11 | 38 | 9 | 0,5 | 4 | S152512R.10005 AlCrN | No |

| 10 | 10 | 80 | 11 | 38 | 9 | 1 | 4 | S152512R.10010 AlCrN | No |

| 12 | 12 | 93 | 13 | 46 | 11 | 0,5 | 4 | S152512R.12005 AlCrN | No |

| 12 | 12 | 93 | 13 | 46 | 11 | 1 | 4 | S152512R.12010 AlCrN | No |

| 12 | 12 | 93 | 13 | 46 | 11 | 2 | 4 | S152512R.12020 AlCrN | No |

| 16 | 16 | 108 | 17 | 58 | 15 | 1 | 4 | S152512R.16010 AlCrN | No |

| 16 | 16 | 108 | 17 | 58 | 15 | 2 | 4 | S152512R.16020 AlCrN | No |

| 16 | 16 | 108 | 17 | 58 | 15 | 3 | 4 | S152512R.16030 AlCrN | No |

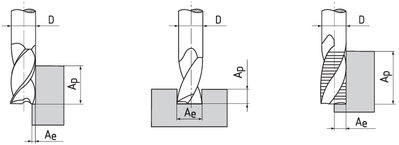

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 4 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1xD | 0,2xD | 210 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1xD | 0,2xD | 175 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1xD | 0,2xD | 120 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 1xD | 0,2xD | 110 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1xD | 0,2xD | 90 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1xD | 0,2xD | 150 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1xD | 0,2xD | 110 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 1xD | 0,2xD | 50 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| S.2 | Titanium, titanium alloys | ≤ 1250 N/mm² | 1xD | 0,2xD | 70 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 1xD | 0,2xD | 120 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

| H.2 | Hardened materials (54 - 60 HRC) | 1920 - 2210 N/mm² | 1xD | 0,2xD | 100 | 0.2 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 6535 HB.

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

Oil coolant.

Coating with very high wear resistance and excellent hot hardness.