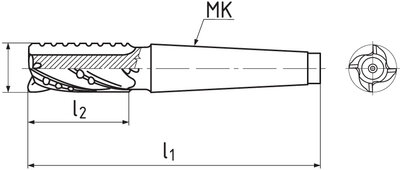

Tapper shank end mills long, semicoarse teeth, 35°, type CB

|

D

k 10 | MK | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 10 | 1 | 115 | 45 | 4 | 423245.100 | Yes |

| 12 | 1 | 123 | 53 | 4 | 423245.120 | Yes |

| 14 | 2 | 138 | 53 | 4 | 423245.140 | Yes |

| 16 | 2 | 148 | 63 | 4 | 423245.160 | Yes |

| 18 | 2 | 148 | 63 | 4 | 423245.180 | Yes |

| 20 | 2 | 160 | 75 | 4 | 423245.200 | Yes |

| 22 | 2 | 160 | 75 | 5 | 423245.220 | Yes |

| 25 | 3 | 192 | 90 | 5 | 423245.250 | Yes |

| 28 | 3 | 192 | 90 | 5 | 423245.280 | Yes |

| 30 | 3 | 192 | 90 | 6 | 423245.300 | No |

| 32 | 4 | 231 | 106 | 6 | 423245.320 | No |

| 36 | 4 | 231 | 106 | 6 | 423245.360 | Yes |

| 40 | 4 | 250 | 125 | 6 | 423245.400 | Yes |

| 45 | 4 | 250 | 125 | 6 | 423245.450 | Yes |

| 50 | 5 | 308 | 150 | 6 | 423245.500 | Yes |

| 56 | 5 | 308 | 150 | 8 | 423245.560 | No |

| 63 | 5 | 338 | 180 | 8 | 423245.630 | Yes |

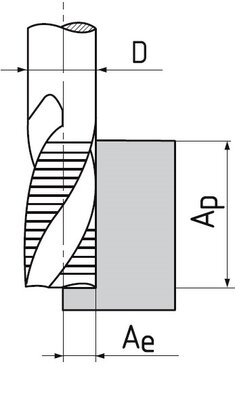

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 10 |

Ø 16 |

Ø 20 |

Ø 25 |

Ø 32 |

Ø 40 |

Ø 50 |

Ø 63 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1xD | 0,5xD | 37,5 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 1xD | 0,5xD | 32,5 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1xD | 0,5xD | 18 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1xD | 0,5xD | 25 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1xD | 0,5xD | 18 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 1xD | 0,5xD | 16 | 0.025 | 0.049 | 0.063 | 0.07 | 0.084 | 0.091 | 0.096 | 0.099 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1xD | 0,5xD | 10 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1xD | 0,5xD | 22 | 0.035 | 0.07 | 0.09 | 0.1 | 0.12 | 0.13 | 0.137 | 0.142 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 1xD | 0,5xD | 8 | 0.025 | 0.049 | 0.063 | 0.07 | 0.084 | 0.091 | 0.096 | 0.099 |

Calculations of cutting conditions

Product attributes

Morse taper shank according to DIN 228 A.

Universal usage. Suitable for materials up to strength 900 MPa.