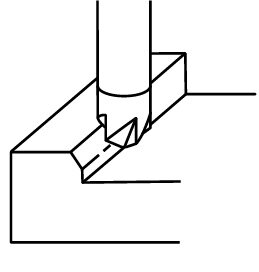

Chamfer end mills, 60°, 90°, type N, plain shank, coating AlTiN

| α | D | l1 | Z | Item code | On stock |

|---|---|---|---|---|---|

| 60° | 6 | 57 | 4 | S350102.060060 AlTiN | Yes |

| 60° | 8 | 63 | 4 | S350102.060080 AlTiN | Yes |

| 60° | 10 | 72 | 4 | S350102.060100 AlTiN | Yes |

| 60° | 12 | 83 | 4 | S350102.060120 AlTiN | Yes |

| 90° | 6 | 57 | 4 | S350102.090060 AlTiN | Yes |

| 90° | 8 | 63 | 4 | S350102.090080 AlTiN | Yes |

| 90° | 10 | 72 | 4 | S350102.090100 AlTiN | Yes |

| 90° | 12 | 83 | 4 | S350102.090120 AlTiN | Yes |

Cutting conditions

Material |

Strenght |

Vc |

fz(mm/z) ∅ 6 |

60° ∅ 8 |

∅ 10 |

∅ 12 |

fz(mm/z) ∅ 6 |

90° ∅ 8 |

∅ 10 |

∅ 12 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 180 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 180 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 100 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 100 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 80 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| P.6 | Tool and treated steels | >1100 N/mm² | 80 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 90 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 80 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| K.1 | Cast Iron (≤ 240 HB) | ≤ 820 N/mm² | 140 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| K.2 | Cast Iron (> 240 HB) | > 800 N/mm² | 100 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 50 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 60 | 0.008 | 0.011 | 0.014 | 0.017 | 0.012 | 0.016 | 0.02 | 0.024 |

Výpočty řezných podmínek

Product attributes

Company norm

Helix angle = 0°.

Rake angle = 0°.

End face design

Oil coolant.

Its advantage is in high hardness in higher temperaures, good oxidation resistance and low temperature conductivity. Universal usage with emphasis on high-speed miling without cooling. Siutable for milling of hard materials.

Universal usage. Suitable for materials up to strength 900 MPa.

Feed direction possibility

End face design

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.