<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

<script type="text/javascript">

(function(a,l,b,c,r,s){_nQc=c,r=a.createElement(l),s=a.getElementsByTagName(l)[0];r.async=1;r.src=l.src=("https:"==a.location.protocol?"https://":"http://")+b;s.parentNode.insertBefore(r,s);})(document,"script","serve.albacross.com/track.js","89861715");

</script>

<script type="text/javascript">

var leady_track_key="Jt85ZWh81xgcWftq";

(function(){var l=document.createElement("script");l.type="text/javascript";l.async=true;l.src='https://t.leady.com/'+leady_track_key+"/L.js";var s=document.getElementsByTagName("script")[0];s.parentNode.insertBefore(l,s);})();

</script>

Home Catalogue Ball nose end mills short, 2-fluted, code 510418, diameter 2 mm

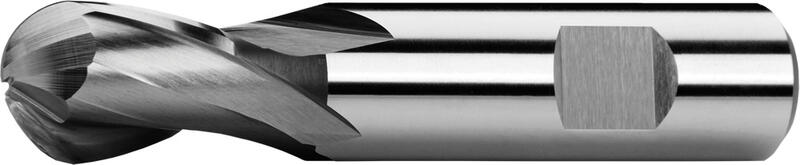

510418.020

High-speed steel HSS Co8

~DIN 1889

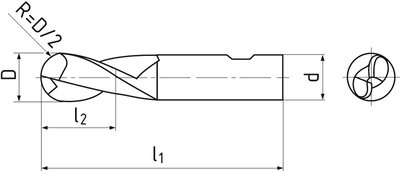

R

D

d

l1

l2

Z

Item code

On stock

1

2

6

48

4

2

510418.020

Yes

Cutting conditions

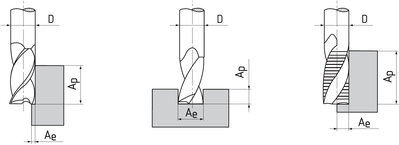

p e c fz (mm/z) Ø 6Ø 8Ø 10Ø 12Ø 16Ø 18Ø 20

P.2 | General construction steels, steel castings

≤ 850 N/mm²

0,5xD

1xD

39

0.022

0.029

0.036

0.044

0.058

0.065

0.073

P.3 | Tool steels low alloyed

≤ 1100 N/mm²

0,5xD

1xD

24

0.022

0.029

0.036

0.044

0.058

0.065

0.073

P.4 | Heat treatable steels

≤ 900 N/mm²

0,5xD

1xD

30

0.022

0.029

0.036

0.044

0.058

0.065

0.073

P.5 | Heat treatable steels

≤ 1100 N/mm²

0,5xD

1xD

24

0.022

0.029

0.036

0.044

0.058

0.065

0.073

P.6 | Tool and treated steels

> 1100 N/mm²

0,5xD

1xD

20

0.0154

0.0203

0.0252

0.0308

0.0406

0.0455

0.0511

M.2 | Corrosion- and acid-proof steels

750 - 850 N/mm²

0,5xD

1xD

15

0.022

0.029

0.036

0.044

0.058

0.065

0.073

K.2 | Cast iron (> 240 HB)

> 800 N/mm²

0,5xD

1xD

25

0.022

0.029

0.036

0.044

0.058

0.065

0.073

S.1 | Chrome-nickel alloys

≤ 1500 N/mm²

0,5xD

1xD

12

0.0154

0.0203

0.0252

0.0308

0.0406

0.0455

0.0511

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 1835 B.

Feed direction possibility

Helix angle = 25°.

Rake angle = 10°.

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.

2026 © ZPS-FN a.s. | All right reserved