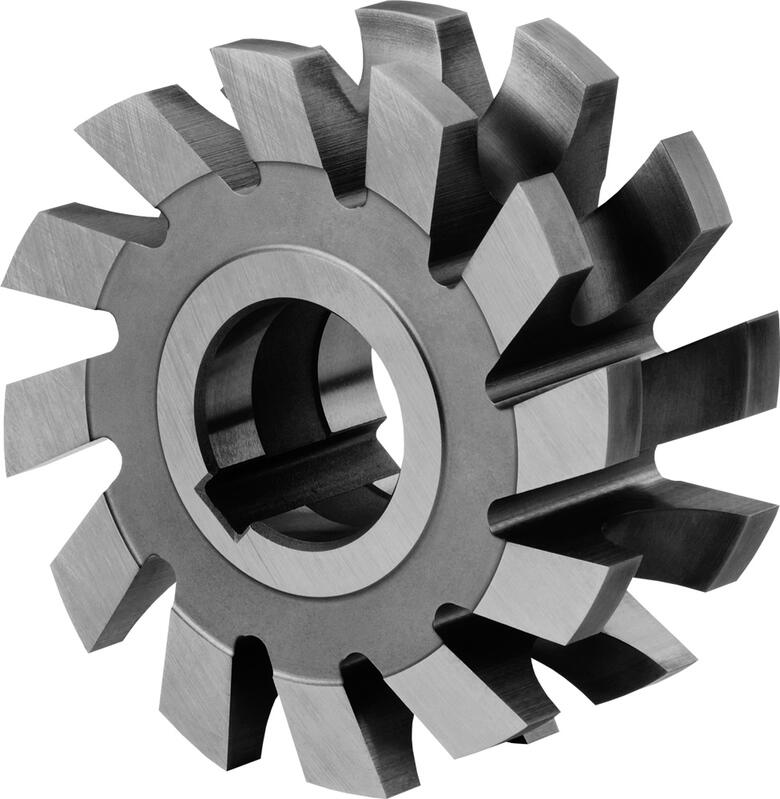

Half circle milling cutters concave

|

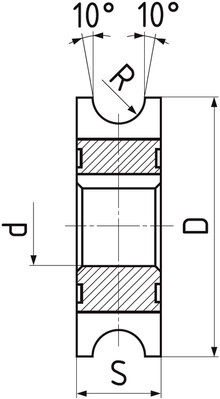

R

H 11 |

D

js 16 | S |

d

H 7 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 1 | 50 | 6 | 16 | 14 | 820075V.010 | Yes |

| 1,25 | 50 | 6 | 16 | 14 | 820075V.0125 | Yes |

| 1,5 | 50 | 8 | 16 | 14 | 820075V.015 | Yes |

| 2 | 50 | 9 | 16 | 14 | 820075V.020 | Yes |

| 2,5 | 63 | 10 | 22 | 14 | 820075V.025 | Yes |

| 3 | 63 | 12 | 22 | 12 | 820075V.030 | Yes |

| 4 | 63 | 16 | 22 | 12 | 820075V.040 | Yes |

| 5 | 63 | 20 | 22 | 10 | 820075V.050 | Yes |

| 6 | 80 | 24 | 27 | 10 | 820075V.060 | Yes |

| 8 | 80 | 32 | 27 | 10 | 820075V.080 | Yes |

| 9 | 100 | 32 | 32 | 10 | 820075V.090 | Yes |

| 10 | 100 | 40 | 32 | 10 | 820075V.100 | Yes |

| 12 | 100 | 44 | 32 | 10 | 820075V.120 | Yes |

| 20 | 125 | 60 | 32 | 10 | 820075V.200 | Yes |

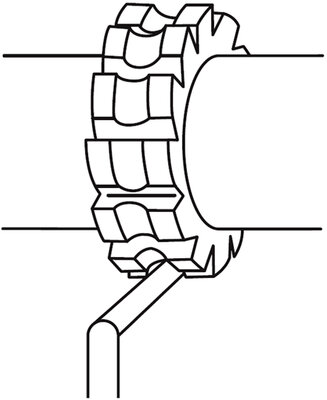

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 50 |

Ø 63 |

Ø 80 |

Ø 100 |

Ø 125 |

|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1xR | 2xR | 37.5 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1xR | 2xR | 18 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1xR | 2xR | 25 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 1xR | 2xR | 16 | 0.056 | 0.07 | 0.084 | 0.098 | 0.0994 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1xR | 2xR | 10 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1xR | 2xR | 30 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1xR | 2xR | 22 | 0.08 | 0.1 | 0.12 | 0.14 | 0.142 |

Calculations of cutting conditions

Product attributes

Straight bore with standard keyway according to DIN 138.

Helix angle = 0°.

Rake angle = 10°.