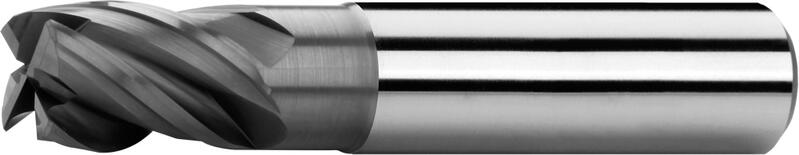

End mills short, 2 teeth cut to centre, 35°-38°, type N, plain shank, coating AlCrN

|

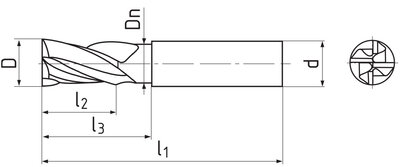

D

h 10 |

d

h 6 | l1 | l2 | l3 | Dn | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|---|

| 3 | 6 | 50 | 5 | 9 | 2,8 | 4 | S140602N.030 AlCrN | Yes |

| 3,5 | 6 | 50 | 6 | 10 | 3,3 | 4 | S140602N.035 AlCrN | No |

| 4 | 6 | 54 | 8 | 13 | 3,8 | 4 | S140602N.040 AlCrN | Yes |

| 4,5 | 6 | 54 | 8 | 15 | 4,3 | 4 | S140602N.045 AlCrN | No |

| 5 | 6 | 54 | 9 | 16 | 4,8 | 4 | S140602N.050 AlCrN | Yes |

| 6 | 6 | 54 | 10 | 17 | 5,7 | 4 | S140602N.060 AlCrN | Yes |

| 8 | 8 | 58 | 12 | 22 | 7,8 | 4 | S140602N.080 AlCrN | Yes |

| 10 | 10 | 66 | 14 | 26 | 9,5 | 4 | S140602N.100 AlCrN | Yes |

| 12 | 12 | 73 | 16 | 28 | 11,5 | 4 | S140602N.120 AlCrN | Yes |

| 14 | 14 | 75 | 18 | 30 | 13,5 | 4 | S140602N.140 AlCrN | Yes |

| 16 | 16 | 82 | 22 | 34 | 15,5 | 4 | S140602N.160 AlCrN | Yes |

| 18 | 18 | 84 | 24 | 36 | 17,5 | 4 | S140602N.180 AlCrN | No |

| 20 | 20 | 92 | 26 | 42 | 19,5 | 4 | S140602N.200 AlCrN | Yes |

Cutting conditions

Material |

Strength |

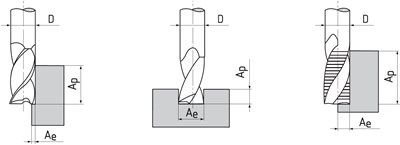

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1,5xD | 0,3xD | 210 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 1,5xD | 0,3xD | 175 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1,5xD | 0,3xD | 120 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 1,5xD | 0,3xD | 110 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1,5xD | 0,3xD | 90 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1,5xD | 0,3xD | 150 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 1,5xD | 0,3xD | 110 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² | 1,5xD | 0,3xD | 50 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| S.1 | Titanium, titanium alloys | ≤ 1250 N/mm² | 1,5xD | 0,3xD | 70 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 1,5xD | 0,3xD | 120 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

| H.2 | Hardened materials (54 - 60 HRC) | 1920 - 2210 N/mm² | 1,5xD | 0,3xD | 100 | 0.015 | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.09 | 0.1 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Helix angle = 35/38°.

Rake angle = 10°.

End face design

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.