Machine taps with spiral flute, 35°, for stainless steel, coating TiCN

|

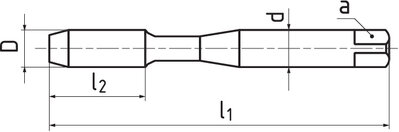

D

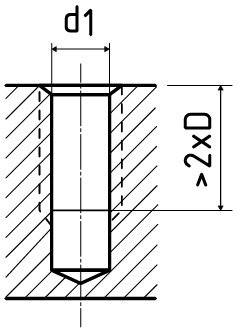

6 H | P | d | l1 | l2 | d1 | Z | a | Item code | On stock |

|---|---|---|---|---|---|---|---|---|---|

| M3 | 0,5 | 3,5 | 56 | 5 | 2,5 | 3 | 2,7 | MT21575.030 TICN | No |

| M4 | 0,7 | 4,5 | 63 | 7 | 3,3 | 3 | 3,4 | MT21575.040 TICN | Yes |

| M5 | 0,8 | 6 | 70 | 8 | 4,2 | 3 | 4,9 | MT21575.050 TICN | No |

| M6 | 1 | 6 | 80 | 10 | 5 | 3 | 4,9 | MT21575.060 TICN | No |

| M8 | 1,25 | 8 | 90 | 13 | 6,8 | 3 | 6,2 | MT21575.080 TICN | No |

| M10 | 1,5 | 10 | 100 | 15 | 8,5 | 3 | 8 | MT21575.100 TICN | Yes |

| M12 | 1,75 | 9 | 110 | 18 | 10,2 | 3 | 7 | MT21575.120 TICN | Yes |

| M14 | 2 | 11 | 110 | 20 | 12 | 3 | 9 | MT21575.140 TICN | No |

| M16 | 2 | 12 | 110 | 20 | 14 | 4 | 9 | MT21575.160 TICN | Yes |

| M18 | 2,5 | 14 | 125 | 25 | 15,5 | 4 | 11 | MT21575.180 TICN | No |

| M20 | 2,5 | 16 | 140 | 25 | 17,5 | 4 | 12 | MT21575.200 TICN | No |

Cutting conditions

Material |

Strength |

Vc |

|---|---|---|

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 8-14 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 6-10 |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² | 6-10 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 8-12 |

Calculations of cutting conditions

Product attributes

Designed for stainless steel

For straight or spiral flutes, for short chipping materials.

Lead of screw thread

ISO Metric coarse thread

Helix angle = 35°.

Angle of thread

Thread standard

Provides high hardness and at the same time good toughness. Its advantage is in low friction ratio. It is applicable for boring of steels with high strength. It has a lower temperature stability – the cooling is necessary (for example with emulsion).