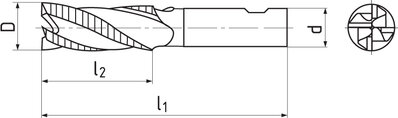

End mills short, 1 tooth cut over centre, 30°, type NR-F, Weldon shank

|

D

k 12 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 6 | 6 | 57 | 13 | 4 | 124518P.060 | Yes |

| 7 | 10 | 66 | 16 | 4 | 124518P.070 | Yes |

| 8 | 10 | 69 | 19 | 4 | 124518P.080 | Yes |

| 9 | 10 | 69 | 19 | 4 | 124518P.090 | Yes |

| 10 | 10 | 72 | 22 | 4 | 124518P.100 | Yes |

| 11 | 12 | 79 | 22 | 4 | 124518P.110 | Yes |

| 12 | 12 | 83 | 26 | 4 | 124518P.120 | Yes |

| 13 | 12 | 83 | 26 | 4 | 124518P.130 | Yes |

| 14 | 12 | 83 | 26 | 4 | 124518P.140 | Yes |

| 15 | 12 | 83 | 26 | 4 | 124518P.150 | Yes |

| 16 | 16 | 92 | 32 | 4 | 124518P.160 | Yes |

| 17 | 16 | 92 | 32 | 4 | 124518P.170 | Yes |

| 18 | 16 | 92 | 32 | 4 | 124518P.180 | Yes |

| 20 | 20 | 104 | 38 | 4 | 124518P.200 | Yes |

| 22 | 20 | 104 | 38 | 5 | 124518P.220 | Yes |

| 24 | 25 | 121 | 45 | 5 | 124518P.240 | Yes |

| 25 | 25 | 121 | 45 | 5 | 124518P.250 | Yes |

| 26 | 25 | 121 | 45 | 5 | 124518P.260 | Yes |

| 28 | 25 | 121 | 45 | 5 | 124518P.280 | Yes |

| 30 | 25 | 121 | 45 | 5 | 124518P.300 | Yes |

| 32 | 32 | 133 | 53 | 6 | 124518P.320 | Yes |

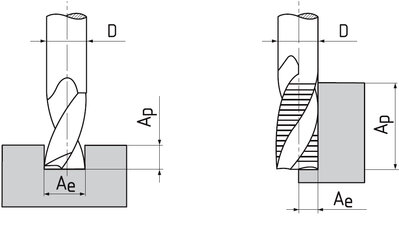

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

Ø 25 |

Ø 32 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 1,5xD | 0,5xD | 45 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 1,5xD | 0,5xD | 39 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

| P.4 | Heat treatable steels | ≤ 900 N/mm² | 1,5xD | 0,5xD | 30 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

| P.5 | Tool steels high alloyed | ≤ 1100 N/mm² | 1,5xD | 0,5xD | 24 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² | 1,5xD | 0,5xD | 15 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 1,5xD | 0,5xD | 35 | 0.02 | 0.025 | 0.035 | 0.04 | 0.07 | 0.08 | 0.09 | 0.1 | 0.12 |

Calculations of cutting conditions

Product attributes

Straight shank with clamping flat (Weldon) according to DIN 1835 B.

Helix angle = 30°.

Rake angle = 12°.

Extra high performance high speed steel with good toughness and great temperature resistance. It is applicable especially for milling of materials with high strength, austenitic steels, steels for warm working, etc.

For machining of materials of lower and medium strength (up to 700 MPa), surface roughness Ra 3,2 and more, in common application can be applied as roughing and finishing tool at the same time.