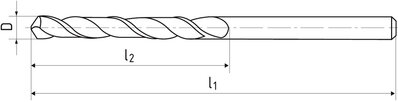

Extra long twist drills with inner cooling, 15xD, coating AlTiN

| D | l1 | l2 | Item code | On stock |

|---|---|---|---|---|

| 2 | 75 | 35,2 | S70112.020 ALTIN | No |

| 2,2 | 80 | 40,5 | S70112.022 ALTIN | No |

| 2,5 | 90 | 45,5 | S70112.025 ALTIN | No |

| 2,8 | 90 | 50,5 | S70112.028 ALTIN | No |

| 3 | 100 | 55,5 | S70112.030 ALTIN | No |

| 3,2 | 100 | 60,5 | S70112.032 ALTIN | No |

| 3,5 | 108 | 65,5 | S70112.035 ALTIN | No |

| 3,8 | 108 | 70,5 | S70112.038 ALTIN | No |

| 4 | 120 | 75,5 | S70112.040 ALTIN | No |

| 4,2 | 120 | 75,5 | S70112.042 ALTIN | No |

| 4,5 | 120 | 80,5 | S70112.045 ALTIN | No |

| 4,8 | 140 | 90,5 | S70112.048 ALTIN | No |

| 5 | 140 | 90,5 | S70112.050 ALTIN | No |

| 5,2 | 140 | 95,5 | S70112.052 ALTIN | No |

| 5,5 | 150 | 100,5 | S70112.055 ALTIN | No |

| 5,8 | 150 | 100,5 | S70112.058 ALTIN | No |

| 6 | 150 | 100,5 | S70112.060 ALTIN | No |

| 6,2 | 148 | 108 | S70112.062 ALTIN | No |

| 6,5 | 160 | 121 | S70112.065 ALTIN | No |

| 6,8 | 170 | 131 | S70112.068 ALTIN | No |

| 7 | 170 | 131 | S70112.070 ALTIN | No |

| 7,5 | 170 | 131 | S70112.075 ALTIN | No |

| 8 | 180 | 141 | S70112.080 ALTIN | No |

| 8,5 | 198 | 155 | S70112.085 ALTIN | No |

| 9 | 208 | 165 | S70112.090 ALTIN | No |

| 9,5 | 208 | 165 | S70112.095 ALTIN | No |

| 10 | 218 | 175 | S70112.100 ALTIN | No |

| 10,5 | 245 | 197 | S70112.105 ALTIN | No |

| 11 | 245 | 197 | S70112.110 ALTIN | No |

| 11,5 | 245 | 197 | S70112.115 ALTIN | No |

| 12 | 255 | 207 | S70112.120 ALTIN | No |

Cutting conditions

Material |

Strenght |

Vc |

fz(mm/r) Ø3 |

Ø5 |

Ø8 |

Ø10 |

Ø12 |

Ø15 |

Ø17 |

Ø20 |

|---|---|---|---|---|---|---|---|---|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² | 68 | 0,125 | 0,16 | 0,25 | 0,315 | 0,315 | 0,315 | 0,4 | 0,5 |

| P.2 | General construction steels, steel castings | ≤ 850 N/mm² | 64 | 0,125 | 0,16 | 0,25 | 0,315 | 0,315 | 0,315 | 0,4 | 0,5 |

| P.3 | Tool steels low alloyed | ≤ 1100 N/mm² | 56 | 0,125 | 0,16 | 0,25 | 0,315 | 0,315 | 0,315 | 0,4 | 0,5 |

| P.6 | Tool and treated steels | > 1100 N/mm² | 49 | 0,063 | 0,08 | 0,125 | 0,16 | 0,16 | 0,16 | 0,2 | 0,25 |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² | 38 | 0,07 | 0,05 | 0,1 | 0,125 | 0,125 | 0,125 | 0,16 | 0,2 |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² | 68 | 0,125 | 0,16 | 0,25 | 0,315 | 0,315 | 0,315 | 0,4 | 0,5 |

| K.2 | Cast iron (> 240 HB) | > 800 N/mm² | 53 | 0,063 | 0,08 | 0,125 | 0,16 | 0,16 | 0,16 | 0,2 | 0,25 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Point angle 135°

With coolant holes

Offers similar qualities as TiAlN, but even higher hardness. Substanial temperature stability. Designed for the most demanding applications. It provides excellent result mainly when combined with HSSE-PM steels (ASP 2030). The milling cutters manufactured from this steel are coated with AlTiN as standard.