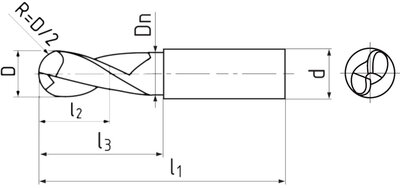

Die sinking short, 2-fluted, λ 15°, type H, plain shank, coating TiSiN

| D | d | l1 | l2 | l3 | Dn | R | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|---|---|

| 3 | 6 | 57 | 4 | 15 | 2,8 | 1,5 | 2 | S511702.030 TISIN | Yes |

| 4 | 6 | 57 | 5 | 16 | 3,8 | 2 | 2 | S511702.040 TISIN | Yes |

| 5 | 6 | 57 | 6 | 20 | 4,8 | 2,5 | 2 | S511702.050 TISIN | Yes |

| 6 | 6 | 62 | 7 | 24 | 5,7 | 3 | 2 | S511702.060 TISIN | Yes |

| 8 | 8 | 68 | 9 | 30 | 7,6 | 4 | 2 | S511702.080 TISIN | Yes |

| 10 | 10 | 80 | 11 | 38 | 9,5 | 5 | 2 | S511702.100 TISIN | Yes |

| 12 | 12 | 93 | 13 | 46 | 11,5 | 6 | 2 | S511702.120 TISIN | Yes |

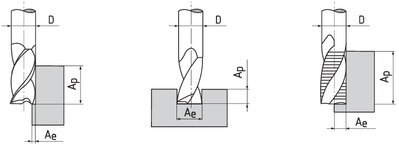

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 4 |

Ø 5 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² | 0.5xD | 0.5xD | 280 | 0.06 | 0.08 | 0.1 | 0.12 | 0.16 | 0.2 | 0.24 | 0.32 | 0.4 |

| H.2 | Hardened materials (54 - 60 HRC) | 1920-2210 N/mm² | 0.5xD | 0.5xD | 280 | 0.06 | 0.08 | 0.1 | 0.12 | 0.16 | 0.2 | 0.24 | 0.35 | 0.4 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

Helix angle = 15°.

Rake angle = 10°.

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.

Designed for milling (finishing) of materials of medium and higher strength (up to 1200 MPa). Surface roughness Ra 3,2; exceptionally even 1,6.

Feed direction possibility

Coating with excellent hardness, high heat and oxidation resistance.It is usually applied to high-speed cutting tools used on CNC machines for machining hardened steels from 50 to 65 HRC.