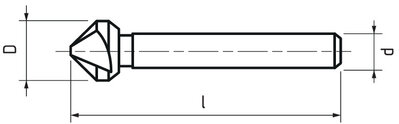

Countersinks, Basic series, coating TiAlN

| D | d | l1 | Item code | On stock |

|---|---|---|---|---|

| 4,3 | 4 | 40 | CS21002.090043 TiAlN | Yes |

| 5,3 | 4 | 40 | CS21002.090053 TiAlN | Yes |

| 6,3 | 5 | 45 | CS21002.090063 TiAlN | No |

| 8,3 | 6 | 50 | CS21002.090083 TiAlN | No |

| 10,4 | 6 | 50 | CS21002.090104 TiAlN | No |

| 12,4 | 8 | 56 | CS21002.090124 TiAlN | Yes |

| 16,5 | 10 | 60 | CS21002.090165 TiAlN | Yes |

| 20,5 | 10 | 63 | CS21002.090205 TiAlN | Yes |

| 25 | 10 | 67 | CS21002.090250 TiAlN | No |

Cutting conditions

Material |

Strenght |

|---|---|

| P.1 | Free-cutting steels, general construction steels | ≤ 600 N/mm² |

| P.1 | Free-cutting steels, general construction steels | ≤ 850 N/mm² |

| P.4 | Heat treatable steels | ≤ 900 N/mm² |

| M.1 | Corrosion- and acid-proof steels | ≤ 750 N/mm² |

| M.2 | Corrosion- and acid-proof steels | 750 - 850 N/mm² |

| M.3 | Corrosion- and acid-proof steels | > 850 N/mm² |

| K.1 | Cast iron (≤ 240 HB) | ≤ 820 N/mm² (≤ 240 HB) |

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm² |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² |

| N.4 | Copper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² |

| S.1 | Chrome-nickel alloys | ≤ 1500 N/mm² |

| S.2 | Titanium, Titanium alloys | ≤ 1250 N/mm² |

| H.1 | Hardened materials (< 54 HRC) | ≤ 1920 N/mm² |

Calculations of cutting conditions

Product attributes

Point angle 90°

Carbide materials are characterised by high compressive strength, high hardness and therefore high wear resistance, but also limited flexural strength and toughness.