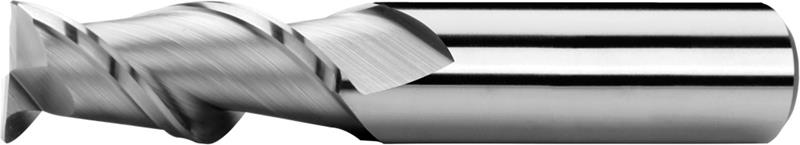

End mills long, 2 teeth cut to centre, 45°, type W, plain shank

|

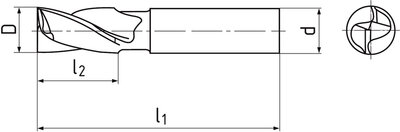

D

h 10 |

d

h 6 | l1 | l2 | Z | Item code | On stock |

|---|---|---|---|---|---|---|

| 3 | 6 | 57 | 8 | 2 | S111602.030 | No |

| 3,5 | 6 | 57 | 10 | 2 | S111602.035 | Yes |

| 4 | 6 | 57 | 11 | 2 | S111602.040 | Yes |

| 4,5 | 6 | 57 | 11 | 2 | S111602.045 | No |

| 5 | 6 | 57 | 13 | 2 | S111602.050 | Yes |

| 6 | 6 | 57 | 13 | 2 | S111602.060 | Yes |

| 7 | 8 | 63 | 16 | 2 | S111602.070 | Yes |

| 8 | 8 | 63 | 19 | 2 | S111602.080 | Yes |

| 9 | 10 | 72 | 19 | 2 | S111602.090 | No |

| 10 | 10 | 72 | 22 | 2 | S111602.100 | Yes |

| 12 | 12 | 83 | 26 | 2 | S111602.120 | Yes |

| 14 | 14 | 83 | 26 | 2 | S111602.140 | Yes |

| 16 | 16 | 92 | 32 | 2 | S111602.160 | Yes |

| 18 | 18 | 92 | 32 | 2 | S111602.180 | Yes |

| 20 | 20 | 104 | 38 | 2 | S111602.200 | Yes |

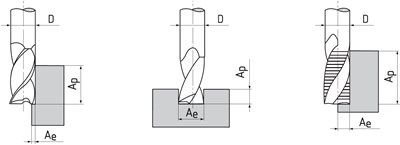

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 3 |

Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 18 |

Ø 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm2 | 1,5xD | 0,2xD | 160 | 0.02 | 0.04 | 0.053 | 0.067 | 0.08 | 0.107 | 0.13 | 0.135 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm2 | 1,5xD | 0,2xD | 220 | 0.02 | 0.04 | 0.053 | 0.067 | 0.08 | 0.107 | 0.13 | 0.135 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm2 | 1,5xD | 0,2xD | 176 | 0.016 | 0.032 | 0.0424 | 0.0536 | 0.064 | 0.0856 | 0.096 | 0.164 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

For machining of soft materials, for example aluminium and non-ferrous metals.

Feed direction possibility