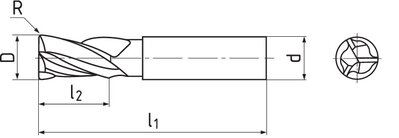

End mills long with corner radius, 1 tooth cut over centre, 44°-46°, typ W, code S111402R, diameter 6 mm, corner radius 0,2 mm, coating ZrN

|

D

e 8 |

d

h 5 | l1 | l2 | R | Z | Item code | On stock |

|---|---|---|---|---|---|---|---|

| 6 | 6 | 57 | 15 | 0,2 | 3 | S111402R.060 ZRN | Yes |

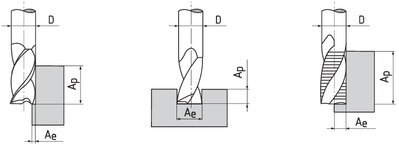

Cutting conditions

Material |

Strength |

Ap |

Ae |

Vc |

fz(mm/z) Ø 6 |

Ø 8 |

Ø 10 |

Ø 12 |

Ø 16 |

Ø 20 |

Ø 25 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| N.1 | Aluminium, Aluminium cast alloys Si (Si ≤ 6%) | ≤ 400 N/mm² | 2xD | 0,4xD | 200 | 0.036 | 0.048 | 0.06 | 0.075 | 0.096 | 0.12 | 0.15 |

| N.2 | Aluminium cast alloys Si (Si ≤ 12%) | ≤ 600 N/mm² | 2xD | 0,4xD | 200 | 0.036 | 0.048 | 0.06 | 0.075 | 0.096 | 0.12 | 0.15 |

| N.4 | Cooper-zinc alloys, cooper-tin alloys | ≤ 800 N/mm² | 2xD | 0,4xD | 500 | 0.036 | 0.048 | 0.06 | 0.075 | 0.096 | 0.12 | 0.15 |

Calculations of cutting conditions

Product attributes

Plain straight shank according to DIN 6535 HA.

For machining of soft materials, for example aluminium and non-ferrous metals.

Feed direction possibility

Oil coolant.

Coating with high corrosion resistance and high hardness with low coefficitent of friction. Ideal for machining aluminum alloys, cupper alloys or plastics.